All over the world, aromas, foodstuffs and flavour stimulants are prepared and processed with amixon® precision mixers

Precision mixers for food processing with aroma compounds

‘Flavour (Άρωμα)’ comes from the Greek word for spice. The taste buds on our tongues recognise five basic tastes: sweet, sour, salty, bitter and umami. In addition, nature offers us more than 10,000 different scents. These are complex chemical compounds. We perceive the aromatic nuances of food and drink with our sense of smell. The combination of taste and smell provides us with the flavour profile.

Fragrances can stimulate the appetite and encourage us to buy something. Synthetic fragrances can create an illusion of well-being and quality, for example in a new car.

What are the advantages for you of working with amixon?

- Process development and testing: With test centres in Germany, the USA, Thailand, Japan, Korea and India, amixon offers the opportunity to optimise mixing processes and develop new products.

- In some places, our mixing plants have been in daily use for over 30 years. That speaks for quality and durability.

- Ideal mixing quality in short cycle times: amixon mixers achieve ideal homogeneity in short mixing cycles. This occurs without heating the product.

- Gentle mixing process: delicate spices and herbs retain their aromas, textures and colours when amixon mixing technology is used.

- Food safety: amixon systems meet and exceed global hygiene standards.

- Empty completely: amixon mixers can empty almost completely.

- Ergonomics in cleaning: Large inspection doors allow easy access to the mixing chamber.

- Flexibility for different batch sizes: amixon mixers are designed to work efficiently at different filling levels (from about 10% to 100%).

- Efficient liquid distribution in powder: amixon mixers guarantee the highest mixing quality - perfectly smooth.

- Energy-efficient mixing process: amixon mixing technology works independently of the filling level - without heating the mixture - without destroying your particles, ...

Three-dimensional motion paths produce ideal random mixtures

Industrial processing of flavours is usually done in precision mixers. In amixon® mixers, powders and liquids are distributed into each other without dead space.

The amixon® mixing principle is called ‘shear stream’.

The helical SinConvex® mixing tool moves the materials to be mixed in three dimensions. At the periphery of the mixing chamber, the powder is conveyed upwards. Once it reaches the top, it flows downwards in the centre. The mixing effect is three-dimensional. In all zones of the upward movement and in all zones of the downward movement, the particles randomly collide and separate; the process is referred to as ‘ideal random mixing’. This process is referred to as ‘ideal random mixing’. It is usually achieved after 50 to 100 revolutions. Ideal mixing qualities are usually achieved within 2 to 5 minutes.

More and more flavours are available in powder form

The reasons for using flavours in powder form are many:

- Longer shelf life and stability: powders are less susceptible to microbes and unwanted chemical reactions.

- Convenient further processing, especially when flavours are mixed with other dry products.

- Easy storage: when properly packaged, powder flavours are easy to store and transport without the need for refrigeration.

- Solid concentrates have a low volume. Transport and storage create a smaller carbon footprint.

The world population is growing and with it the market for convenience foods. New products are constantly coming onto the market. The pace of innovation is favoured by an ever-increasing range of refined raw materials.

Seemingly trivial topics such as powder mixing and powder wetting are becoming increasingly important. The more complex the material composition, the more gently the mixing process must proceed. This is precisely the speciality of the amixon® mixers.

Distributive mixing means gentle mixing

The homogeneity of a powder mixture is achieved without the powder particles being broken or crushed. The shape and size of all particles are retained.

This requirement is difficult to meet in practice because solid particles rub against each other when they move relative to each other.

The following factors can influence success or failure:

- Hardness of the particles

- Bulk density of the mixture

- Size of the particles

- Fluidisation capability of the powder mixture

- Grain size distribution of the powder mixture

- Size of the batch

- Flow properties (internal friction)

- Presence of liquids

- Roughness of the particle surfaces

- Roundness of the particles

- ......

amixon® has been researching and developing the topic of ‘gentle mixing’ for more than 40 years and can offer outstanding solutions. Ideal mixing qualities are achieved with minimal motor power. amixon® mixers are used for dry, moist and wet powders.

- Vertical double shaft mixer

- Cone mixer

- Gyraton® mixer

amixon® mixers are equipped with spiral mixing tools. They convey the material to be mixed upwards in the outer area of the mixing chamber. From there, the material moves downwards. In the centre of the mixing chamber, the material trickles downwards. A rotation is superimposed on all flows. Since each particle moves at a different speed relative to the neighbouring particles and has a different speed, the movement is completely random.

This flow results in a technically ideal random mixture. amixon® mixers achieve ideal mixing qualities because they mix without dead space. It does not matter whether the filling level is 100% or only 10%. The only thing that matters is the number of revolutions. The speed plays a subordinate role.

When processing flavours, gentle mixing is particularly important.

- Many liquid flavours are mixed with agglomerated powders. The agglomerates must then be preserved. No dust must be created during mixing.

- There is an increasing number of microencapsulated liquid flavours. These ‘dry-liquid-powders’ have a delayed flavour release. They look like normal powders, but they must be gently agitated during mixing. The quality of the flavour is only maintained if the microcapsules are not damaged.

Disagglomeration means intensive mixing

Disagglomeration and dispersing mixing involves breaking up agglomerates and lumps during the mixing process. The primary particles, which are then present in a scattered manner, are distributed randomly, resulting in an ideal random mixture.

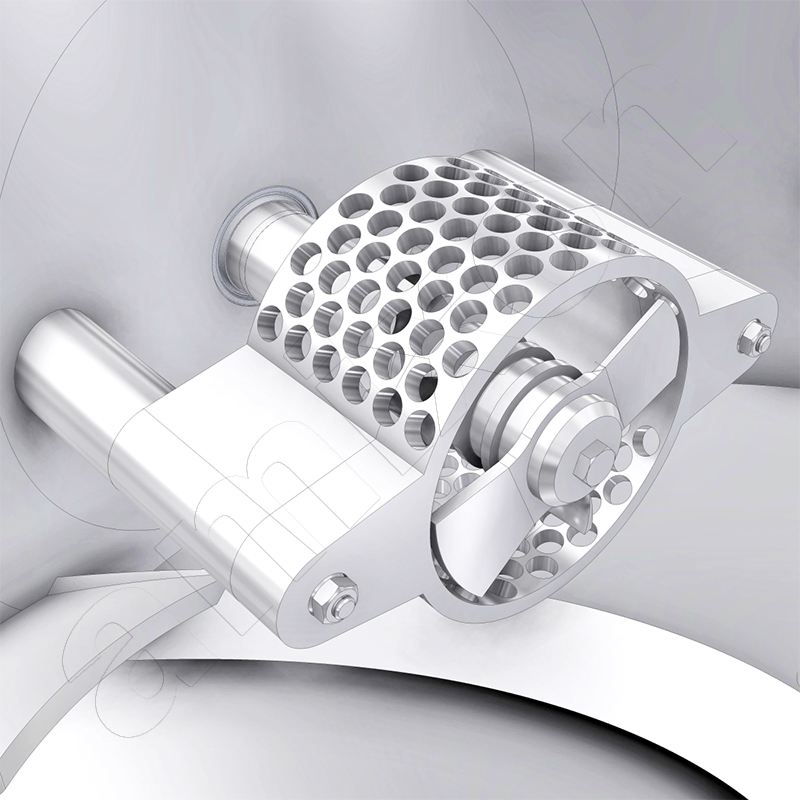

Strictly speaking, the mixing process described above, ‘distributive mixing’, is carried out with a much faster rotational movement of the mixing tool. In addition, one or two fast-rotating knives/high-shear blades/rotor-stator systems are installed in the mixing chamber. During the mixing process, the particles of the mixture undergo intensive shearing, impact and compression effects. The power input into the mixture is proportional to the second or third power of the circumferential speed. Depending on the duration of the mixing process, the mixture may heat up measurably.

All amixon® mixing processes work very well for dry, moist and wet powders.

Deagglomeration mixing is very important for flavour processing. Many spices and essences are highly viscous. They require a higher power input. Otherwise, unwanted clumping would occur.

Flexibility: different filling levels

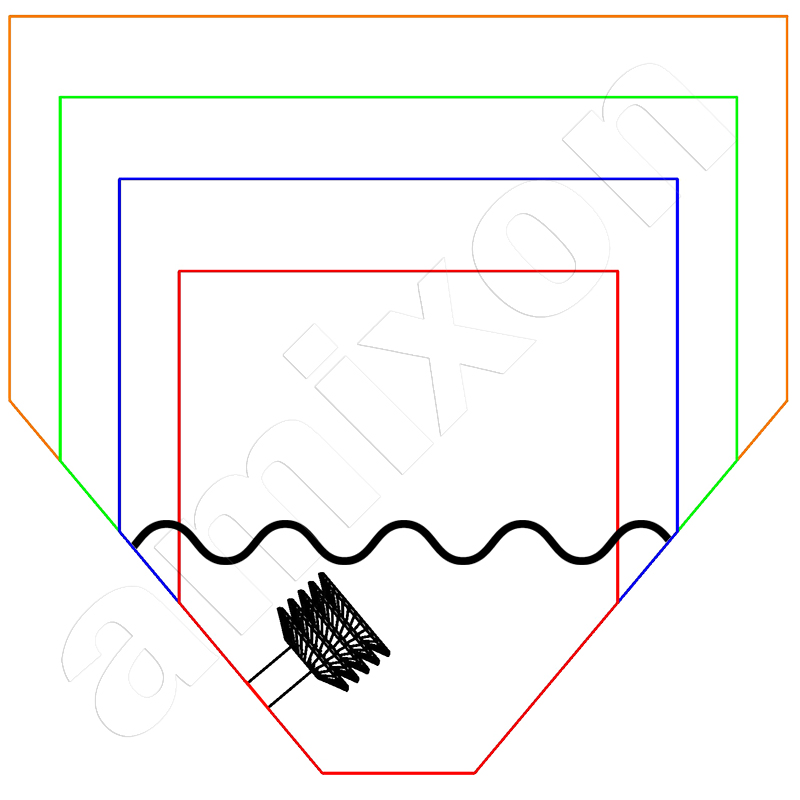

amixon® cone mixers are manufactured congruently. The cone shape is always the same regardless of the size. Shown on the left: the rapidly rotating deagglomeration tool protrudes from the cone. It can always be installed in the same place regardless of the size. The minimum filling level is marked as a black wave. For large amixon® conical mixers, the minimum filling level can be set very low. This means increased flexibility for production operations.

Depending on the operating mode, one and the same amixon® mixer can perform both distributive and deagglomerative mixing. Even at different filling levels.

Ergonomics and hygiene

amixon® can equip your mixer with one or more inspection doors. You can also determine the size of the inspection door.

- OmgaSeal® is an exceptionally hygienic design.

- When closed, the inspection door has no dead space.

- The inserted polymer seal cannot fall out of the groove.

- The polymer seal is easy to remove and easy to install.

- The polymer seal does not stick.

- The seal is durable.

- The seal remains permanently sealed.

- amixon® documents the FDA compliance of all polymer materials.

- amixon® meets the current EHEDG and FDA requirements for both dry and wet operation.

All parts that come into contact with the product are seamlessly welded and ground. Amixon® realises the grinding and surface qualities according to the respective customer specifications. Even mirror-polished surfaces are possible; in special cases, the surfaces are also electro-polished.

Tests, advice, constructive design

As already mentioned, every mixing operation has its own operating philosophy. In this respect, the requirements for a powder mixer are always individual. amixon® can provide good advice based on more than 40 years of experience. Put us to the test! For process trials, amixon has over 40 test mixers in the technical centres in Paderborn, Memphis/USA, Mumbai/India, Tianjin/China, Busan/Korea and Osaka/Japan. The process engineers have many years of market knowledge in the various continents.

All components of the amixon® mixers are manufactured in-house. Only engines and gearboxes (from German production) are purchased.

Requirements for the mixing technology when processing powdered flavours

The market for convenience foods is growing rapidly. This applies in particular to the instant food sector:

- Great taste

- Balanced nutritional value. LESS sugar, salt, fat, colourings and preservatives. MORE: vitamins, fibre, antioxidants

- Fast preparation

- Balanced price-performance ratio

- Long shelf life, stability and hygiene

- Environmentally friendly packaging

amixon® can optimise the quality-determining mixing step for you. We look forward to receiving your assignment.

© Copyright by amixon GmbH