Innovative processing technologies invented by amixon® mixing technology experts

“If we follow in the footsteps of others, we can never become the leader. amixon® likes to go its own way. We take pleasure in developing innovative solutions for the processing challenges of our customers.”

Stefan Ruberg, Owner & Managing Director

amixon® looks back on a 40-year tradition and has established vertical precision mixers worldwide. Every industry has its own specific requirements. amixon® has developed many innovative inventions and patents. The optimum mixing result is always the main focus. But our innovations also include improving automation, operator ergonomics, cleaning and hygiene.

Learn more about the trendsetting technologies of amixon®.

Our mixing systems, vacuum mixing dryers and synthesis reactors are among the best of their class.

New amixon® test center

On the occasion of the company's 40th anniversary, amixon® has built 4 new synthesis reactors for trial purposes. In our newly built devices, substances can be refined, modified, dried or synthesized in 200-litre batches.

amixon® can fulfill demanding process requirements here:

- Vacuum up to 25 bar overpressure

- Temperature up to 350°C

- Alloy 59 material for corrosive products

- Explosion-proof environment (Gasex and Dustx requirements)

Please visit us with your original product! We look forward to your challenges!

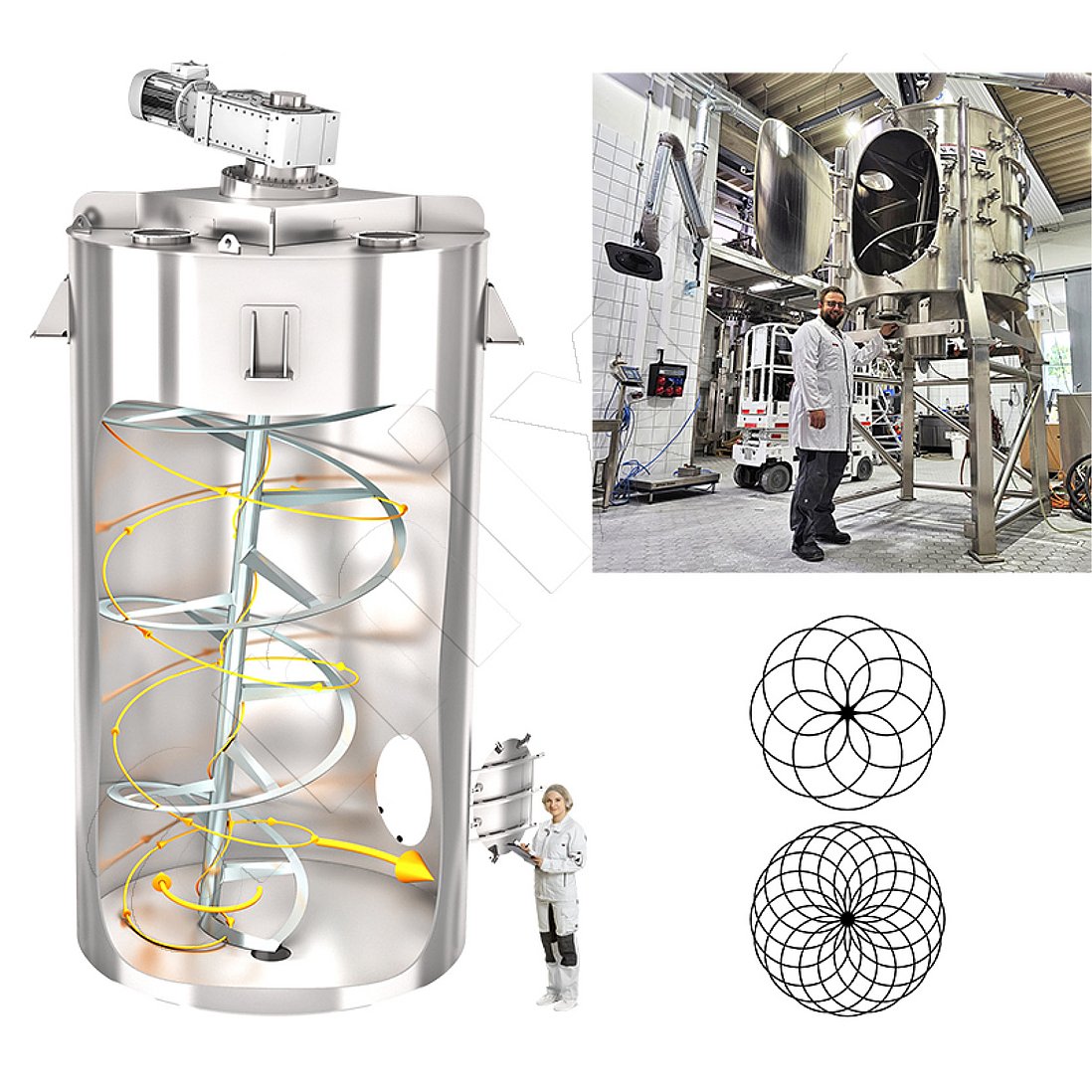

Gyraton® mixer

For the homogenization of large batches:

- Technically ideal and precise

- with minimum drive power

- with a compact mixing system

The Gyraton® mixer is another new development from amixon®. It can be used for all types of bulk goods. Regardless of whether they flow well or poorly, are dry or wet. Regardless of whether they have different grain sizes and bulk densities. A Gyraton® test mixer is available for test mixtures of up to 3 m³.

SpherHelics® hollow sphere mixer from amixon®

On the occasion of the company's 40th anniversary, amixon® has presented another new development. The mixing chamber is a hollow sphere. A helix mixing tool rotates inside. The mixing tool axis deviates from the line of gravity by 20 degrees. The flow generated in this way is a "synthesis" of vertical mixer and horizontal mixer.

The test mixer shown here has special properties:

- It is particularly easy to clean.

- Powder batches of up to 400 liters can be mixed ideally, precisely and gently.

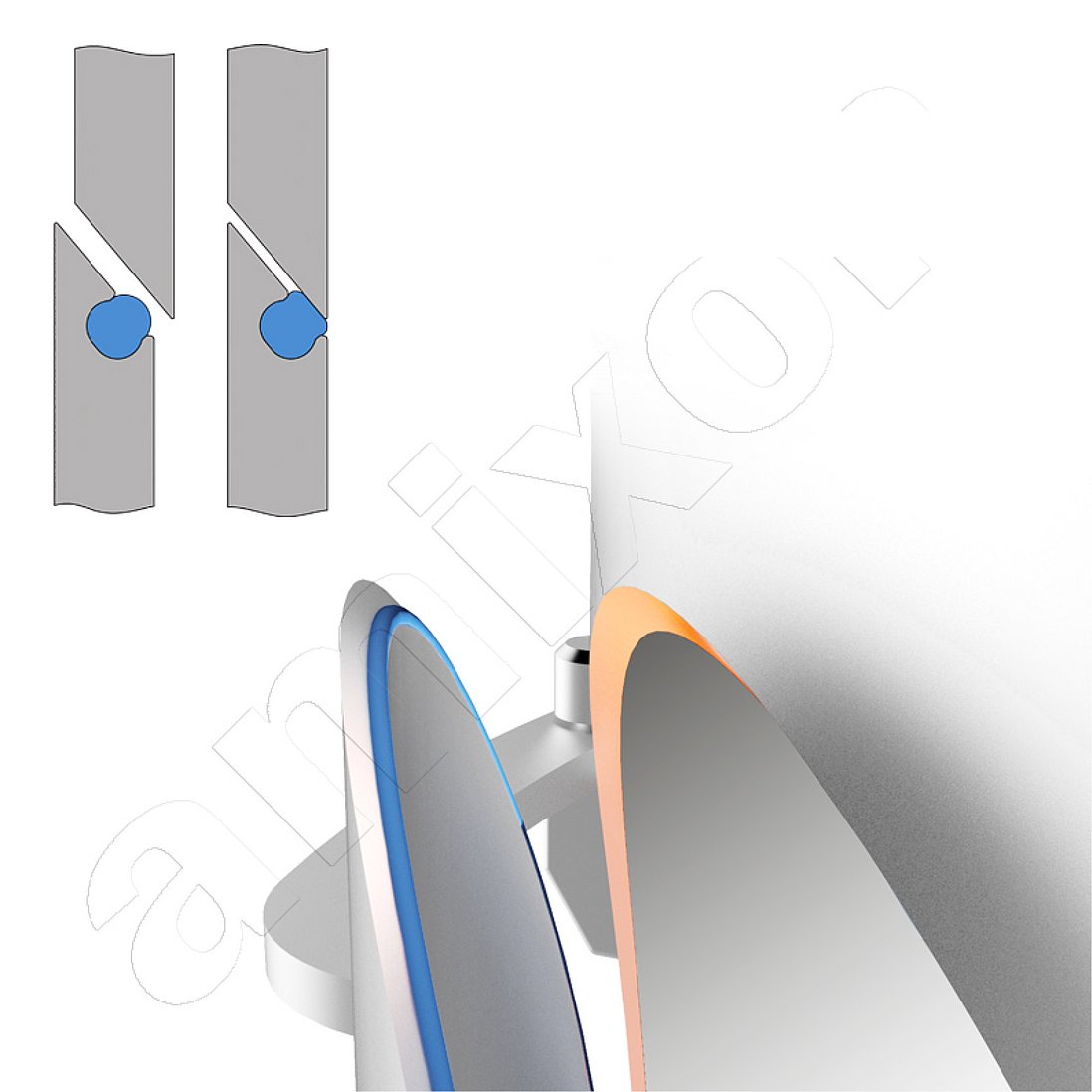

Clever-Cut® inspection hatches with OmgaSeal® seal

amixon® mixers are equipped with large, ergonomic inspection doors that allow access to the mixing room. The special feature is that the inspection doors of the amixon® mixers seal "free of dead space". The O-ring seals very close to the mixing goods. An innovative manufacturing process ensures that amixon® inspection doors remain permanently sealed. This is also the case with frequent opening. Another special feature: The groove that the O-ring is inserted into is curved backwards. The O-ring is clamped and cannot be lost. The pressed seal is reminiscent of the Greek letter omega.

KwickKlamp® door clamps

Self-locking closure system that is easy to operate with one hand. The key features of amixon® KwickKlamps® are summarized in a few words:

- Sturdy construction guarantees a long service life

- Secure closure. Automatic opening is impossible

- Very ergonomic: high force transmission in the final phase of pressing

- Adjustable contact pressure, otherwise hygienically optimized without screw connections

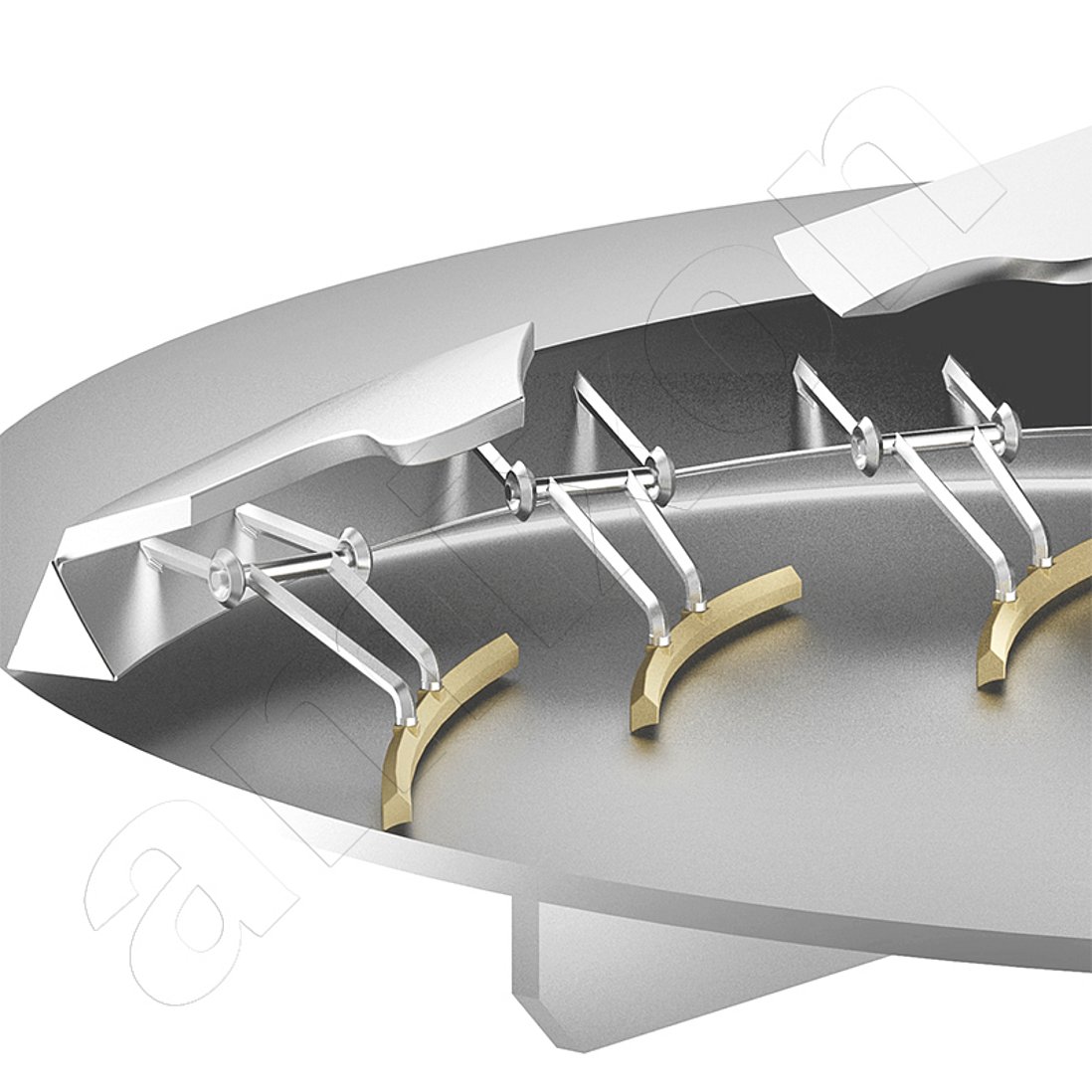

ComDisc® complete discharge

Even the last residue in the mixer is ideally homogeneously mixed and should be sold. This avoids waste and minimizes cleaning effort. ComDisc® improves the batch yield to up to 99.97%. Self-cleaning takes place fully automatically.

The ComDisc® tools lift up during the mixing process. They operate in the current shadow. They only lower in the final phase of emptying. They then push the remaining, ideally mixed, product into the outlet port of the mixer. The food-safe plastic has a long service life. It is easily replaceable.

KoneSlid® Mixer

The KoneSlid® mixer is an innovative further development of the amixon® conical mixer. KoneSlid® mixers achieve ideal mixing qualities within 30 to 120 seconds - regardless of the filling level or the properties of your bulk goods. The mixing process is particularly gentle and careful. The granulometry of your powders is not changed.

In the KoneSlid® mixer, the discharging process is not only carried out within a few seconds, but also takes place completely.

KoneSlid® mixers are ideal if the mixing goods have sensitive particle structures: spray-dried agglomerates, tablet masses, moist bulk materials that should not agglomerate, nanostructured high-performance ceramics, ....

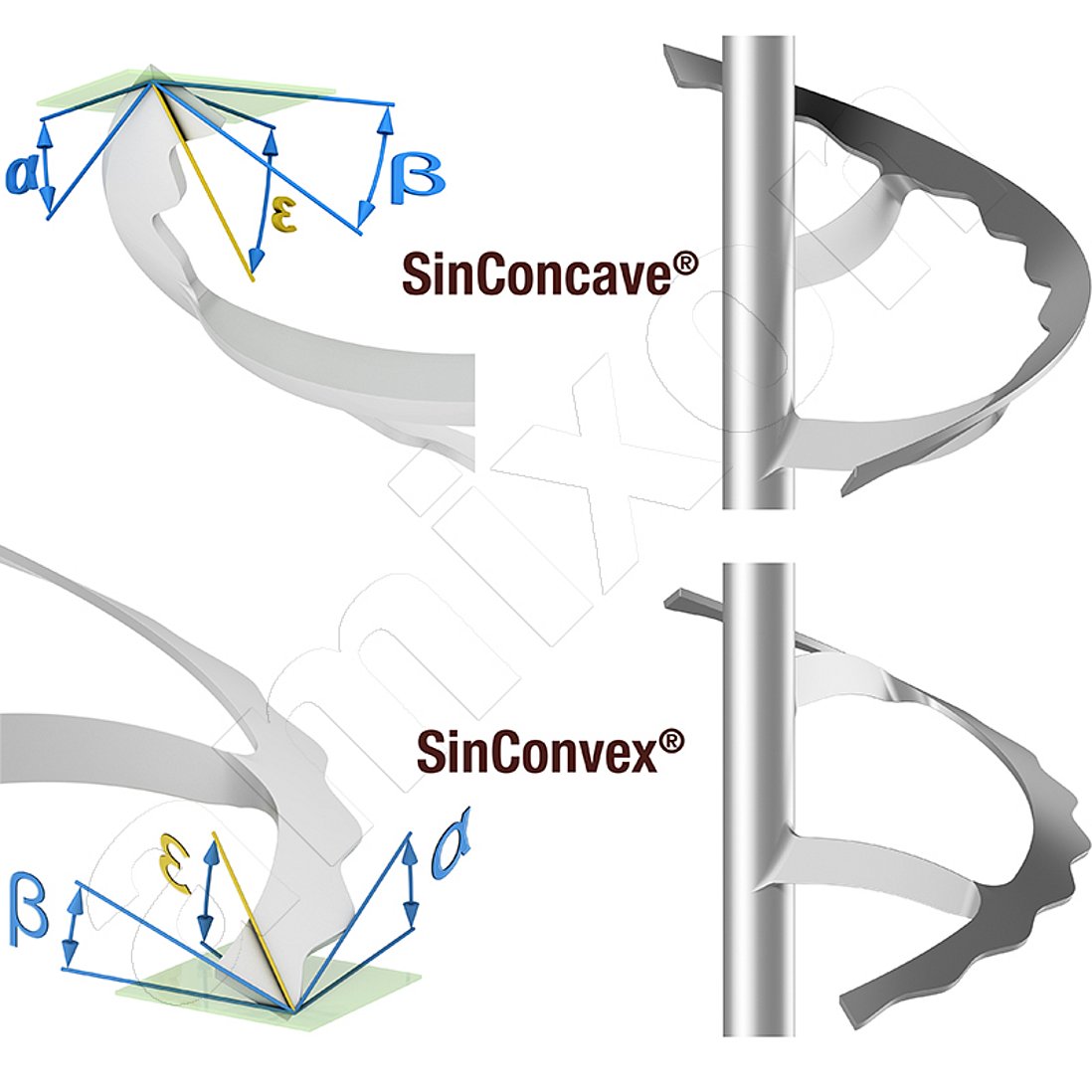

SinConvex® Mixing Blades

The innovative SinConvex® helical mixing blade initiates a three-dimensional powder flow within the mixing goods. Powders flow upwards in a spiral current along the periphery of the mixing chamber. After reaching the top, they flow back downwards along the mixing shaft. The mixing effect occurs three-dimensionally within the boundary areas between the two macro flows.

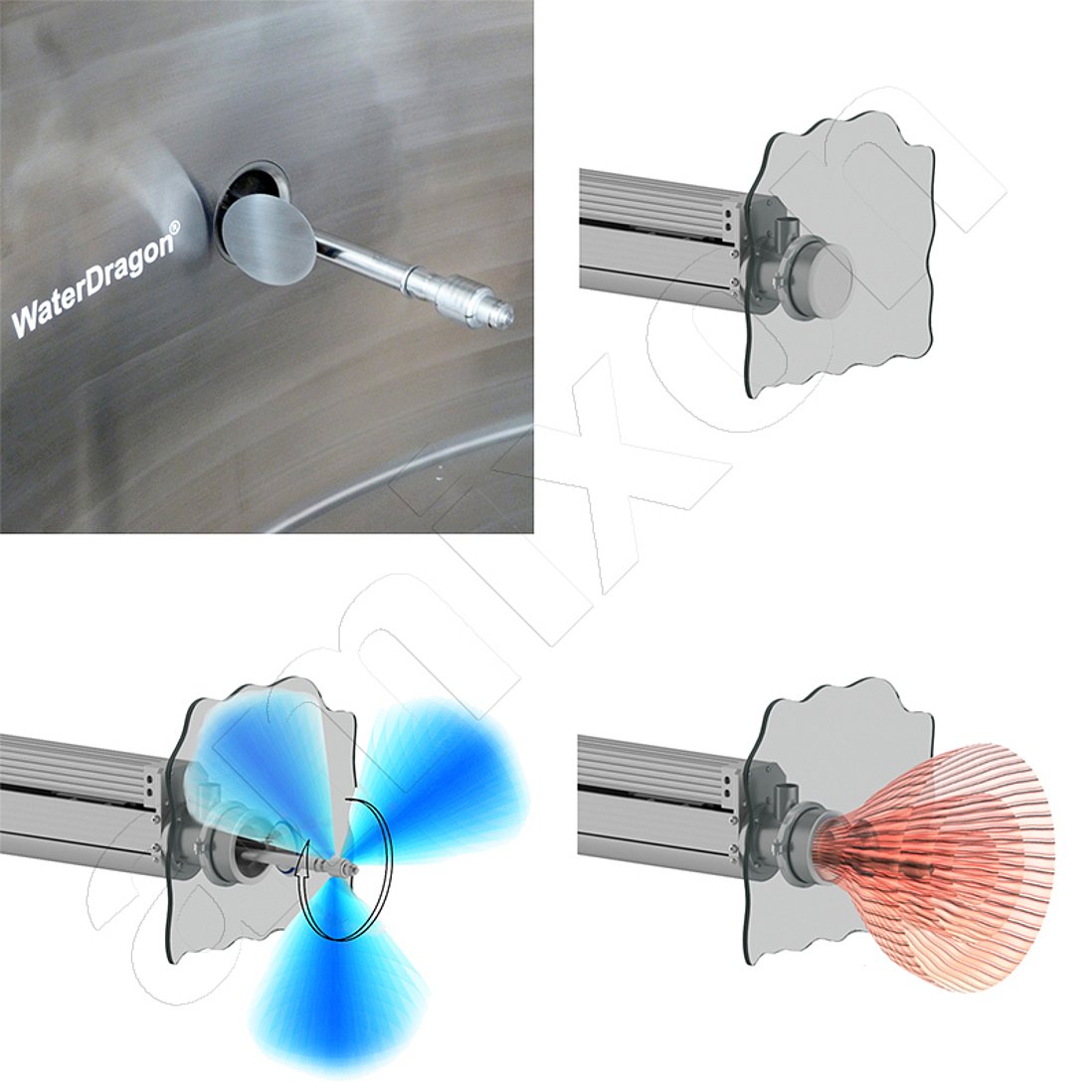

WaterDragon® Wet Cleaning System

WaterDragon® is a system for automatic wet cleaning and drying of an amixon® mixer / vacuum mixer dryer / synthesis reactor. The pressure of the washing water is approx. 3.5 bar, the temperature can be up to 90 °C.

A large opening cross-section is available for the incoming hot air. After the mixer has dried, the spray lance moves out of the mixing chamber. The opening then closes without any dead space.

Depending on the size of the machine, several WaterDragon® systems can be installed in the mixer.

Manufacturing portfolio of amixon®

amixon® is a global trendsetter and quality leader in the field of vertical precision mixers. We look forward to your specific task. All machines are available for trials, even for large batches of up to 3 m³. Risks that can arise from scale-up calculations can thus be eliminated.

amixon GmbH

Halberstaedter Strasse 55

33106 Paderborn

Germany

Telephone: +49-5251-688888-0