Excursus: HM twin-shaft mixer for preparing baking powder powder

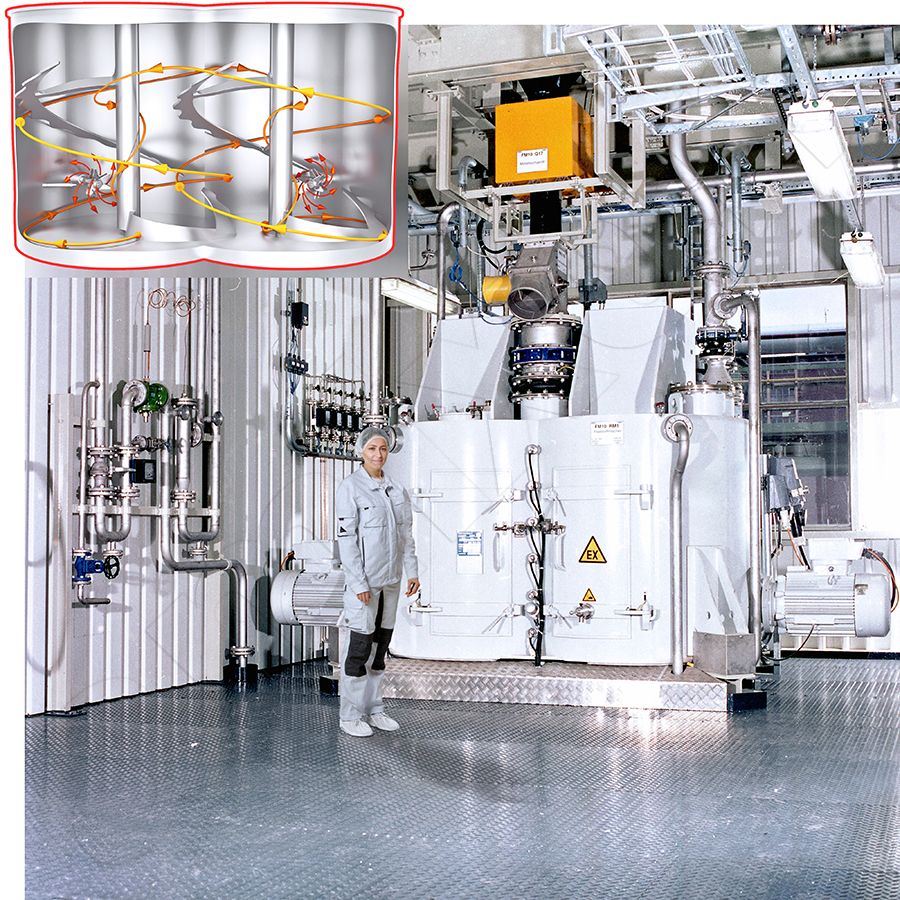

amixon® powder mixer with 2 m³ usable volume. Designed for particularly fast and gentle preparation of baking agents.

The powders in a baking agent are usually dusty and finely dispersed. The powdery baking mix components have different affinities towards the liquid phase. Some powders absorb a present liquid very quickly. Other powders allow the liquid to bead up on them. Still others want to coat liquid droplets.

Good solution: amixon® twin-shaft mixer

This amixon® powder mixer with a net capacity of 3.5 m³ is designed for the particularly fast and gentle processing of powdered baking agents. The mixer has a particularly large discharge valve.

An amixon® twin-shaft mixer can handle the entire process spectrum:

- gentle mixing with minimal energy input

- intensive dispersing mixing with particularly high power

- variable filling levels

- many liquids can be added at the same time. These can be low or high viscosity fats, oils, baking extracts, oleoresins, lecithins or enzymes.

- fast and complete emptying (optionally down to a few grams of residual amount)

- the mixing material does not heat up (or only minimally) in the mixer.

If you would like to learn about a continuous method of agglomeration, then please read here.

MultiStep process for agglomeration

The shortest mixing time is achieved when all components are added to the mixer at the same time and mixed. This is useful in more than 90% of cases.

Some formulations contain relatively high proportions of liquid materials. In these cases, there is a risk that the mixture will subsequently be less flowable. In such cases, the ‘MultiStep’ method is recommended.

- First, solid components in powder form are fed into the mixer and mixed.

- Then the liquid components are metered and intensively mixed in. The mixer then stops.

- Further powder components are added. The mixing tools and agitators are then started.

- The added powders coat the wetted particles.

- Further liquid components are metered in.

In this way, very small agglomerates are formed in layers, which behave like fine, free-flowing powders.

© Copyright by amixon GmbH