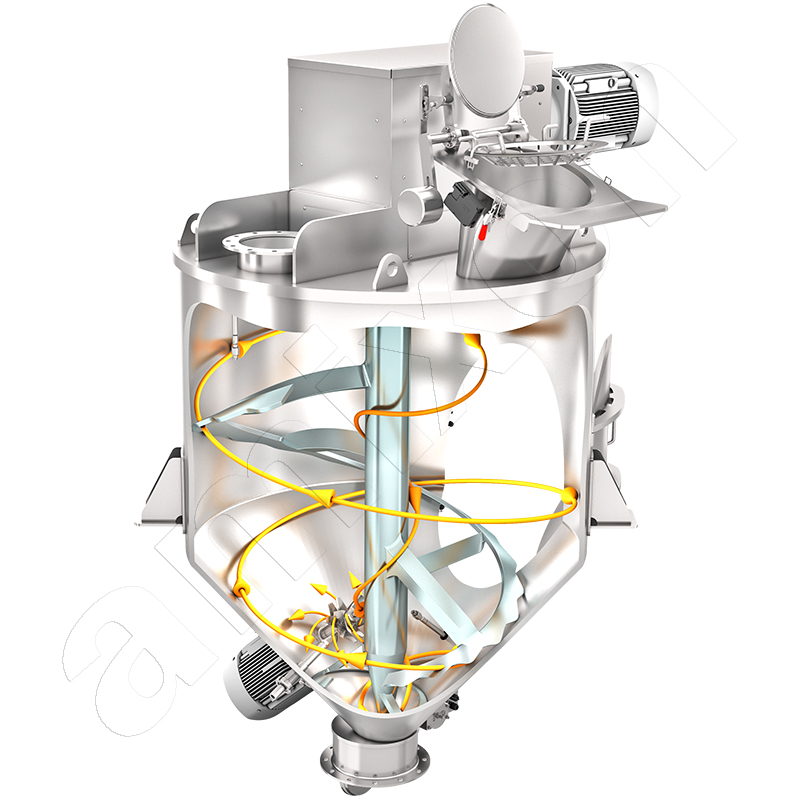

Dosing and mixing device. The spiral mixing tool rearranges the mixing materials three-dimensionally, without any dead space.

amixon® conical mixer mixes either continuously or batchwise

Vertical precision mixer continuously blends powders and liquids

This amixon® conical blender is ideal for achieving the best mixing results in a range of industries. In the case of continuous blending, each component requires a separate continuous metering device. In this case, the number of powdery components is limited to five. There are five gravimetric metering devices.

Perfectly mixed powder from the start to the end of the campaign

In contrast to conventional continuous mixers, there is no product loss at the beginning of the continuous mixing campaign with amixon® AMK-type mixers.

At the beginning of the process, all dosing systems adjust to the mass flow of the main component. The system continuously corrects itself. The mixing chamber is closed during this phase. The synchronisation phase is only complete when each individual dosing system is conveying the correct mass fraction per minute. This process also includes the correction of any dosing errors that occurred previously.

The mixing chamber is now about half full. The mixing tool is started. After about 1 to 4 minutes, an ideal mixing quality is achieved in the mixing chamber. Now the shut-off valve of the mixer is opened slightly. The escaping mass flow is so great that the filling level in the mixing chamber remains constant. Filling level sensors in the mixing chamber or load cells under the mixer control the position of the shut-off valve.

The three-dimensional mixing effect is free of dead space

The mixing principle is a continuous vessel flow. The finished product is ideally homogeneous. The machine can also be operated in batches for mixing complex special formulations. This amixon®cone mixer can mix 10 m³ batches. This takes about six minutes. The finished product can be filled directly into silo vehicles.

The filling levels may vary from 20% to 100%. In each case, ideal mixing qualities are achieved. The mixer can be used flexibly. Even small mixing orders are produced with the same quality.

In the event of frequent product changes, complete emptyingis particularly important to avoid carryover. The amixon® conical mixer can empty free-flowing powders down to 0.001 per cent. Optionally, air nozzles can blow off any remaining dust. Large inspection doors allow for quick visual inspection.

Continuous production of refractory materials

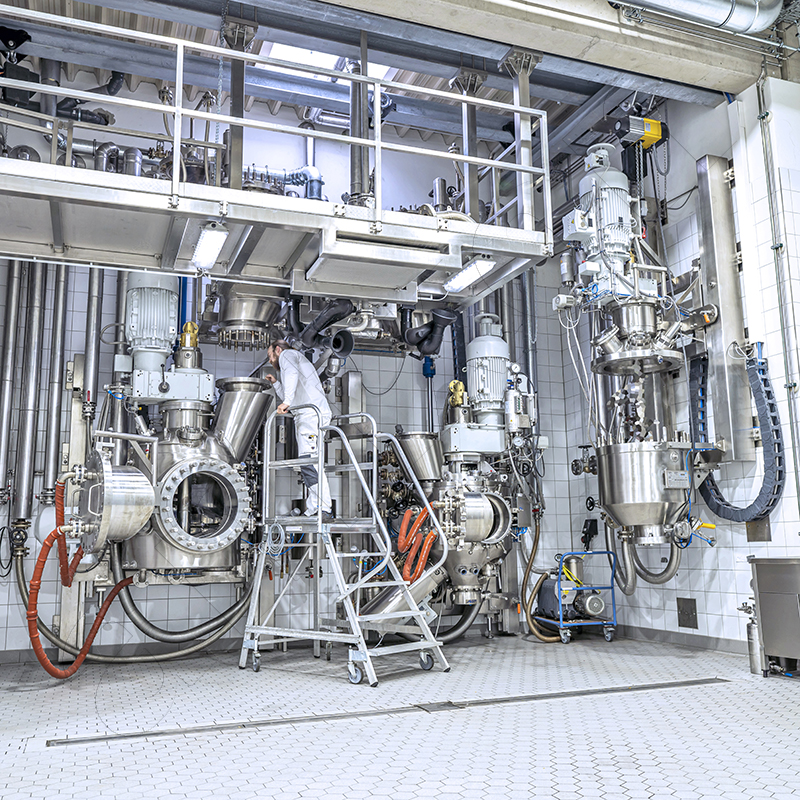

This amixon® cone mixer is mounted on load cells. As a batch mixer, it can homogenise up to 10 m³ of mixture. Ideal mixing qualities are achieved. The same device usually works as a continuous mixer and easily mixes 200 t/h and more. In this case, materials are mixed that serve as fireproof linings in the foundry industry.

Due to their abrasiveness, the mixing tools are provided with a wear-resistant coating.

Mixing tests in the amixon® technical centre are particularly convincing when high mixing qualities are required

Please feel free to use our technical centre for your tests. Based on your requirements, we will arrange a suitable test setup. Here we can demonstrate the continuous mixing process with your original materials.

amixon® has more than 30 test mixers of various sizes in Paderborn. This means that we can assure you of the best results in advance. amixon® also maintains test centres in China, India, Japan, Korea, Thailand and the USA.

Image: amixon® conical mixer, shown here as a container mixer. This mixer can also be operated discontinuously or continuously. A limited selection of continuously operating powder dosing systems is available in the technical centre.

Continuous intensive mixing, agglomeration/granulation

A special form of powder mixing is agglomeration. Primary particles are bound to one another by various binding mechanisms. This results in roundish agglomerates. This process is often referred to as agglomeration. In principle, agglomeration can be carried out in batches or continuously.

The amixon® continuous mixer presented here also works continuously. amixon® ring layer mixing granulators can mix, moisten and agglomerate powders very effectively. However, only in continuous operation. The residence time of the mixture in the mixing chamber is comparatively short. Often it is only 5 to 15 seconds. Nevertheless, the mixing intensity is very high. This is due to the relatively high speed.

We can demonstrate this granulating process in the amixon® technical centre on request.

.

© Copyright by amixon GmbH