Fat coating of decorating sugar

The materials used for the coating are, for example,

- powders with a very small particle size

- high-melting fats

- solids dissolved in liquids

- powders suspended in liquids

- polymers dissolved in solvents

- glues

- lacquers

- .....

Example of use: Finely ground sugar is completely coated with fat. This ensures that it does not melt, even when sprinkled over hot baked goods. The appearance of the sugar is similar to wet snow.

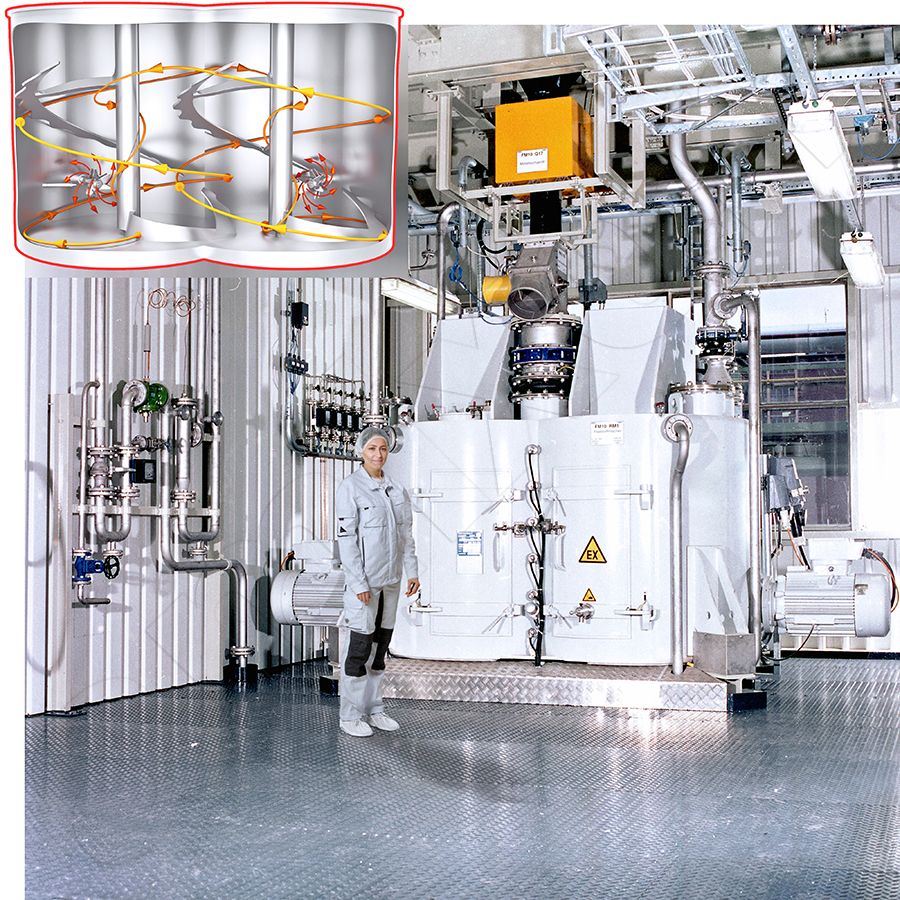

After processing in the amixon® machine, each particle is coated with fat. amixon® powder mixers and dryers can be cleaned antibacterially: ergonomically comfortable, manually, automatically, dry or wet. The CleverCut® doors are hygiene highlights.

Advantages:

The mixture is:

- hydrophobic

- dust-free

- free flowing and easy to dose

- not affected by temperature changes

- little adhesion

- looks like powdered sugar

Coating protects powders and the environment

Sometimes powder particles need to be protected from external influences. Or the environment needs to be protected from the particles. For example, salt with a fat coating is often used to decorate fresh fish in the sales counter. It should only melt when the salt is heated in the pan or saucepan. Fat-coated powdered sugar is used to decorate Christmas biscuits. If the sugar were not coated, it would melt due to the moisture in the biscuit.

Fine soft iron particles are coated with a lacquer and then pressed into a magnet. All iron particles are surrounded by an electrical insulating layer.

Powdered medications are coated to delay their effect. Spices can be coated to preserve their aromas and essential oils.

Almost all disperse goods can be coated. In exceptional cases, even liquid droplets can be coated with powder: ‘Dry-Liquid’.

Almost all powders can be coated in amixon® mixers/vacuum dryers/synthesis reactors

Depending on the type of coating, completely different mixing processes must take place. The intensity of the mixing process is linked to temperature curves. Energy input and temperature curve are the most important parameters. The mixing process can be coupled with vacuum and overpressure. It can be continuous or discontinuous.

Coating processes are similar to agglomeration processes and are rarely simple. As a rule, many tests have to be carried out to a) determine the appropriate mixing systems, b) optimise the process parameters, c) anticipate market opportunities and d) estimate the economic benefits.

amixon® has more than 30 processing machines available at its own test centre in Germany. In addition, we have technical centres in Thailand, China, Japan, Korea and the USA. Based on forty years of experience, we can helpfully support our customers in product and process development. We warmly invite you to contact us and use our test equipment.

In any case, we guarantee you a high level of know-how gain. amixon® is a trendsetter in many areas of ‘vertical mixing’, especially when it comes to mixing quality, efficiency and hygiene. The amixon® team is looking forward to your visit.

© Copyright by amixon GmbH