Manufacturing nutritional supplement powders and effervescent tablets

The selection of a suitable powder mixer plays a crucial role in the quality of powdered nutraceuticals. This is partly because modern nutraceuticals contain extraordinary substances: Ashwagandha, Rhodiola Rosea, Panax Ginseng, L-Theanine, CDP-Choline (Citicoline), Lion's Mane (Hericium erinaceus), hydrolysed collagen, mycoproteins, peptide-enriched amino acids, probiotics & prebiotics, Moringa, Astaxanthin, bioavailable magnesium,.....

They are added to the base powder in powder or liquid form!

amixon mixers are particularly suitable for mixing heterogeneous material systems quickly, gently and precisely.

Gentle mixing and good instant properties

Even if a food supplement tastes good and works well, it will only be accepted by the consumer if it can be prepared quickly. The powder mixture should be dust-free, flow well and not clump. It must also dissolve quickly.

Gentle mixing with amixon® mixers ensures that agglomerated powders dissolve easily in water, juices or shakes. In addition, a pleasant texture contributes to a soft mouthfeel, which promotes acceptance and long-term use of the product.

amixon® mixers blend at low speeds, minimising shear forces and abrasion between particles. This is important for sensitive ingredients such as adaptogens, probiotics, Reishi, Cordyceps, Lion's Mane, black garlic extract, or nootropics. They are often in encapsulated or coated form.

Regarding the picture: Instant properties improved: agglomerated fat-containing powders were treated with lecithin. Then they dissolve and disperse even in water. Good sinking behaviour accelerates wetting.

Mixing quality and protection

amixon® mixers also set the standard in terms of sustainability and energy efficiency. Thanks to their high efficiency, amixon® mixers operate at low peripheral speeds. Nevertheless, the mixing time is very short, regardless of whether the mixer is full or only 30% full. This explains the particularly low energy consumption.

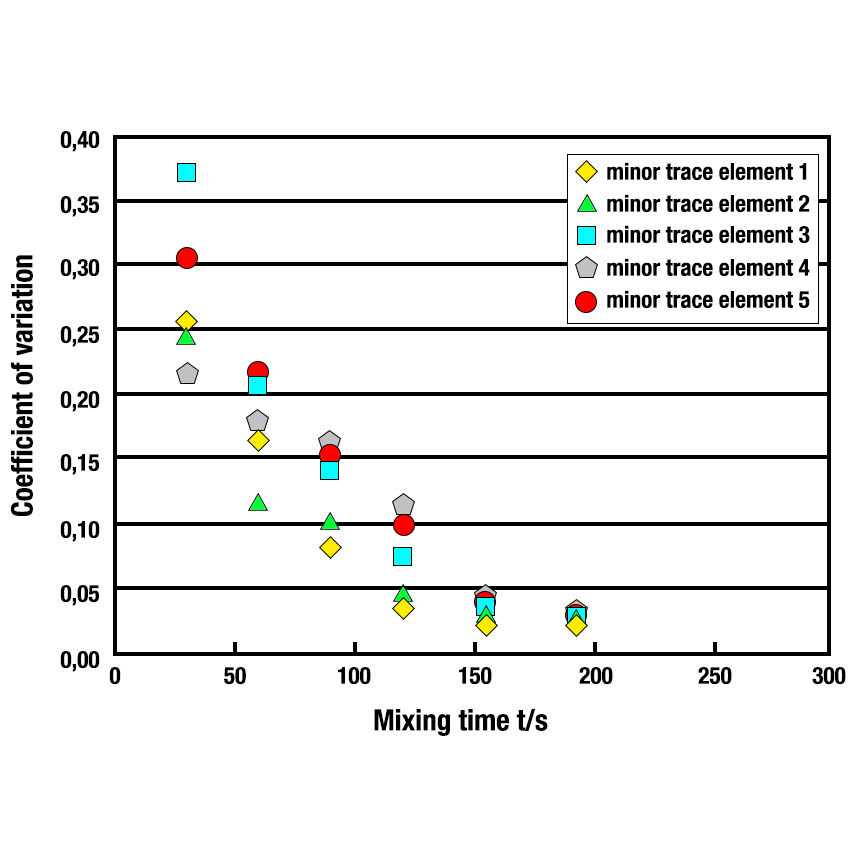

Dry, moist or suspended goods are mixed three-dimensionally. The flow principle works independently of differing particle sizes, bulk densities and flow properties. After only about 40-160 revolutions, amixon® mixing tools achieve ideal mixing qualities that cannot be optimised in practice.

amixon® always achieves the highest mixing quality, which cannot be improved in practice. No matter how long the mixing takes or which mixer is used.

Complete emptying and cleaning

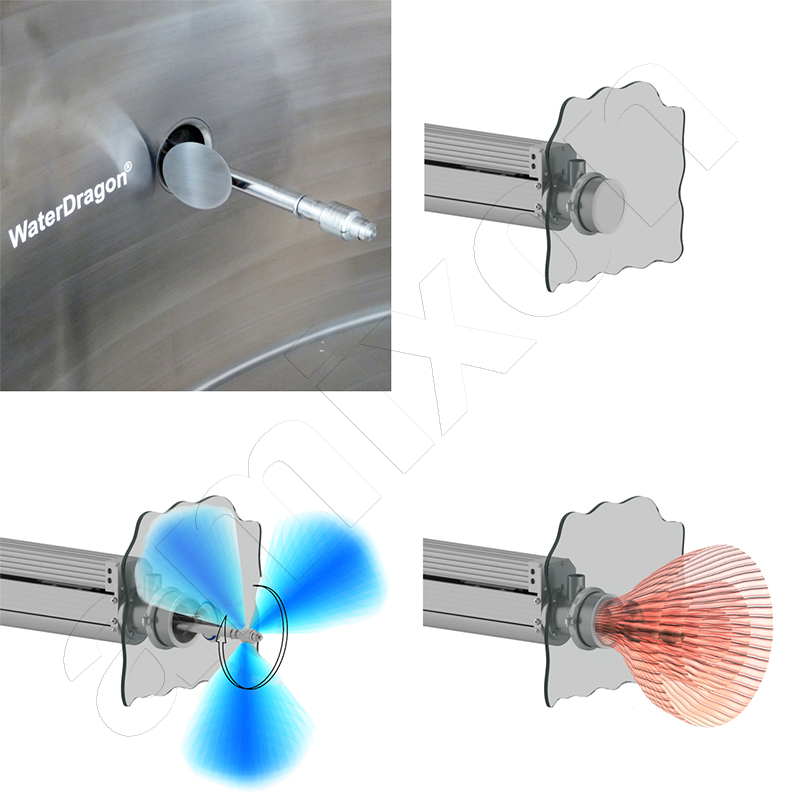

amixon® relies on the highest hygienic standards for the powder processing of nutraceuticals. All our powder mixers meet the requirements of EHEDG, GMP and FDA. With our innovative WaterDragon® wet cleaning system, we also ensure autonomous and thorough wet cleaning. For manual dry cleaning of the powder mixer, amixon® offers quick and easy access with its large CleverCut® inspection doors.

When wet cleaning, water consumption is minimal, which conserves resources and significantly reduces the specific carbon footprint.

Image description: ComDisc® tools remove the last powder residues from the mixing chamber. This is done quickly and without segregation. ComDisc® tools are virtually wear-free. They can be wet-cleaned and sterilised.

© Copyright by amixon GmbH