amixon® helps with the dimensioning of large vacuum mixer dryer systems

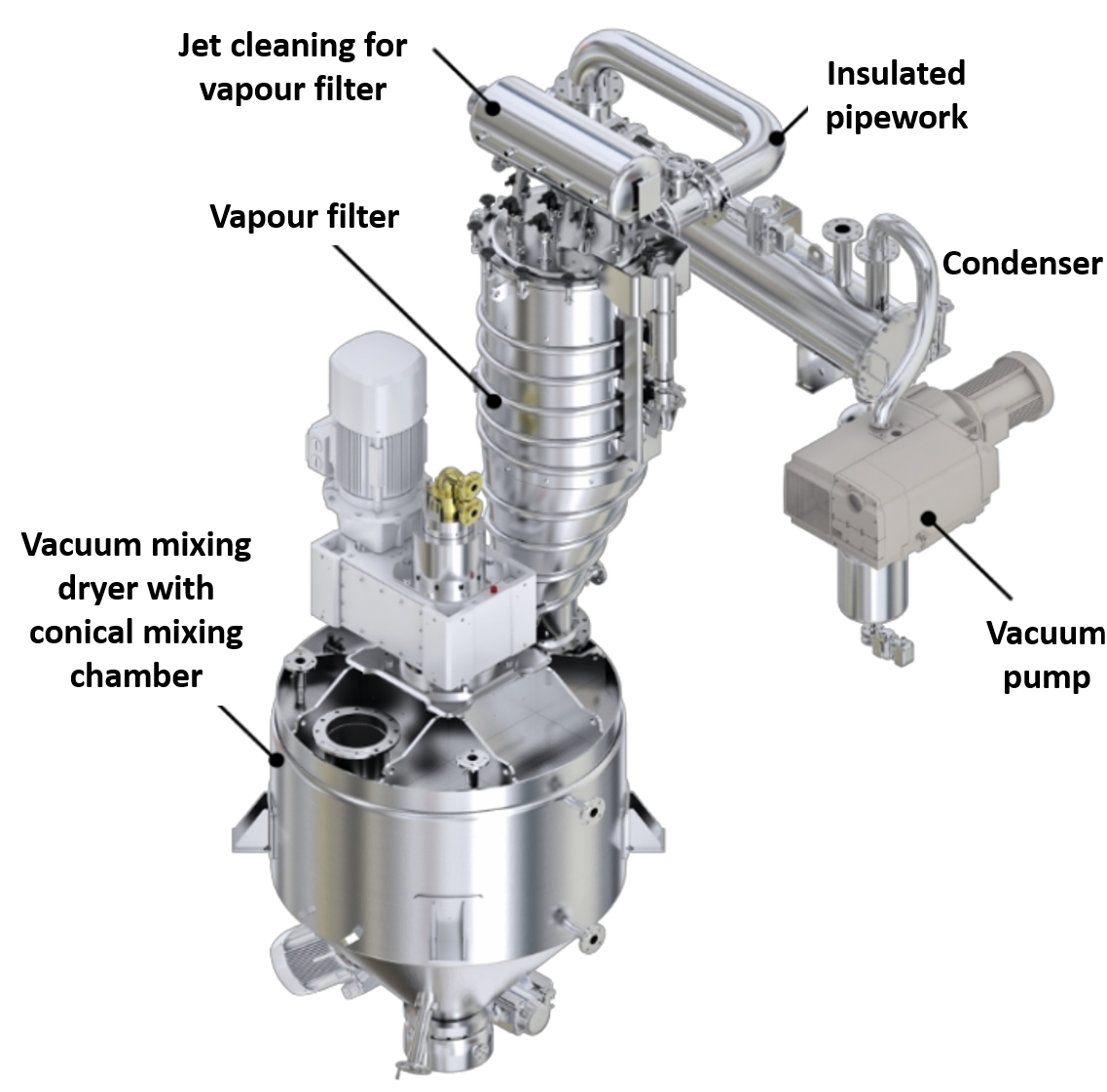

amixon® vacuum mixing dryers and synthesis reactors are used for almost all types of bulk solids and suspensions. Due to the large specific heat transfer surfaces, amixon® devices are also used as evaporators.

The compact amixon® vacuum dryers are characterized by the following properties:

- outstanding energy efficiency

- very gentle product movement

- large specific heat transfer surface

- very high drying speed

- gentle drying due to targeted vacuum setting

- ideal mixing quality

- particularly hygienic design

- amixon® apparatuses are also used as sterile reactors in the biochemical and pharmaceutical industries.

How can amixon® help with the transfer of laboratory results to technical scale?

When new products or processes are developed, questions of technical implementation must be examined in parallel. Scaling up from a test tube to an industrial plant is not trivial.

The pilot plant is used to define process parameters that lead to similarly good results as those previously achieved by the researchers in the test tube.

amixon® is a manufacturer of process engineering systems and has its own pilot plants. The systems there are fully functional. They are dimensioned in such a way that they can be used to design large-scale industrial plants.

Practically all bulk material mixing/refining and vacuum drying processes can be demonstrated with amixon® in the technical center. The pressure in the mixing chamber can be varied from 5 mbar to 26 bar (absolute pressure). The temperature can be varied from sub-zero to 350°C.

This allows customers to quickly find out how well and quickly a synthesis reaction or vacuum drying process works with their product.

How do you extrapolate from a pilot plant to a large-scale plant?

Difficulties arise when the industrial plant to be set up is 100 times larger than the process machine in the pilot plant. For thermokinetic issues, geometric similarity considerations fail. Practical know-how in the application of thermodynamic calculations helps here.

amixon® helps with extrapolation to process machines that are many times larger than the test plant. The accuracy of our calculation methods has been proven time and time again by amixon®. Namely, whenever the large-scale system in the industrial environment achieves or exceeds the calculated performance.

amixon® is happy to invite customers from near and far to take part in trials and promises them very good results in advance. We can do this thanks to decades of experience.

Drying tests in the amixon® technical center are always target-oriented and provide a high level of knowledge. amixon® protects the information shared with you from third parties. This means that the exchange of information always remains confidential.

Drying tests differ from classic mixing tests. The process time is considerably longer. A lot of data is recorded during the drying process in the amixon® technical center. This is largely automated.

This leaves enough time to discuss constructive details. A detailed factory tour should always take place. Some customers use the time to carry out mixing tests for the subsequent process. Others use the time for agglomeration tests.

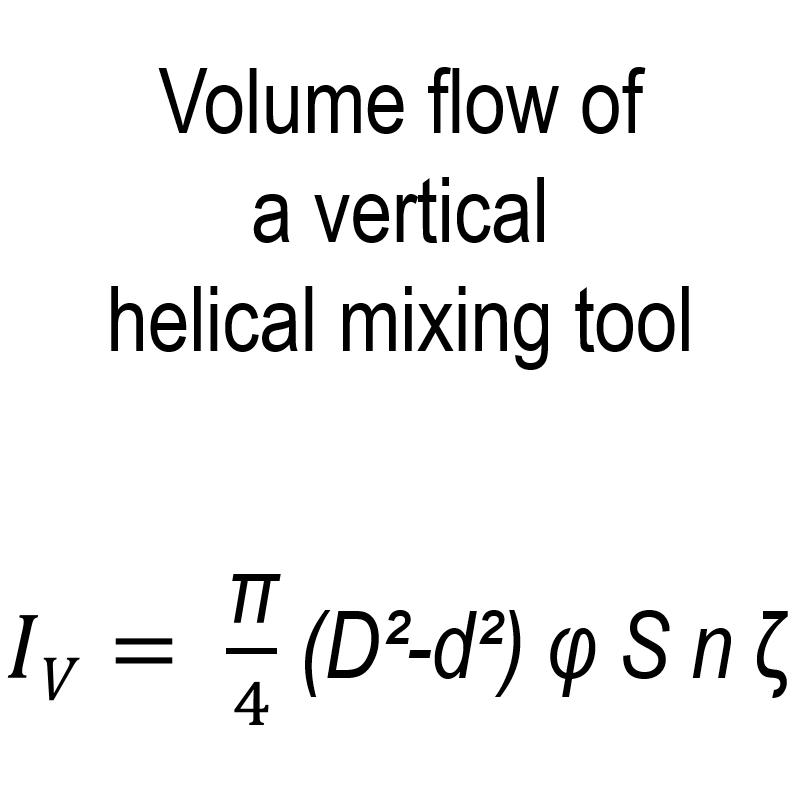

How can the flow of powders in an amixon® vertical mixer be calculated?

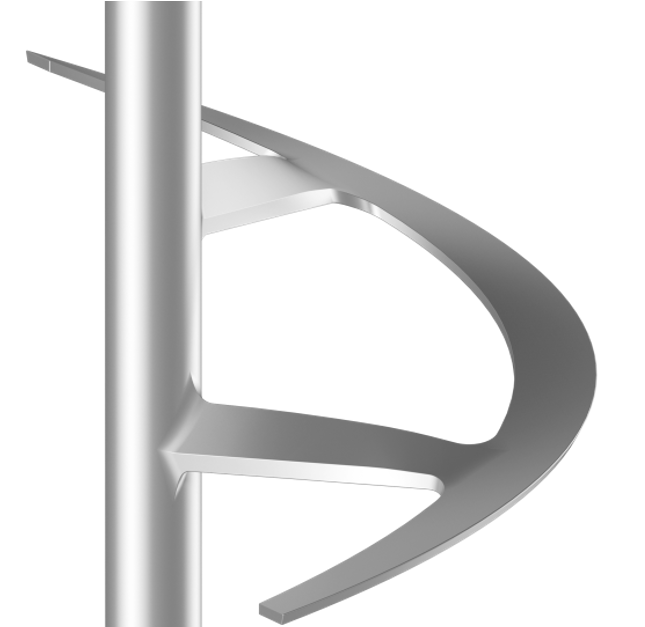

amixon® mixers mix three-dimensionally and produce ideal mixing qualities that cannot be improved in practice. This is achieved by the mixing spiral conveying the mix upwards without any dead space and gravity allowing the mix to flow downwards. The product current Iv can be described approximately as follows.

Iv: Conveying capacity of a vertical mixing spiral

D/ d: Outer/inner diameter of the spiral

φ: Filling degree

S: Pitch of the spiral

n: Rotational frequency

ζ: Speed coefficient

In this respect, the specific mixing capacity of amixon® mixers is always the same regardless of the size, provided that the geometric ratios are congruent.

amixon® has various synthesis reactors/vacuum mixing dryers in Paderborn. Some have a conical mixing chamber. Some have a flat bottom.

Are there any special features of processes that take place at high temperatures and high pressures?

Tests can also be carried out under extreme process conditions in the amixon® technical center:

- System pressure in the process area up to 25 bar overpressure: The thicker container walls influence the heat transfer. On the other hand, the temperatures in the process area can be changed extremely quickly by changing the system pressure. If the system pressure in the process area is increased, gas-solid reactions, for example, can be favoured. For example, diffusion processes ....

- Heating up to 350°C: Conventional polymer seals fail when temperatures permanently exceed 240 °C. Then only metallic sealing systems or graphite gaskets can be used.

- Fine vacuum of 1 mbar absolute: Such absolute pressure requires the apparatus and all communicating connecting lines to be extremely tight. This applies in particular to the sealing of the agitator shaft.

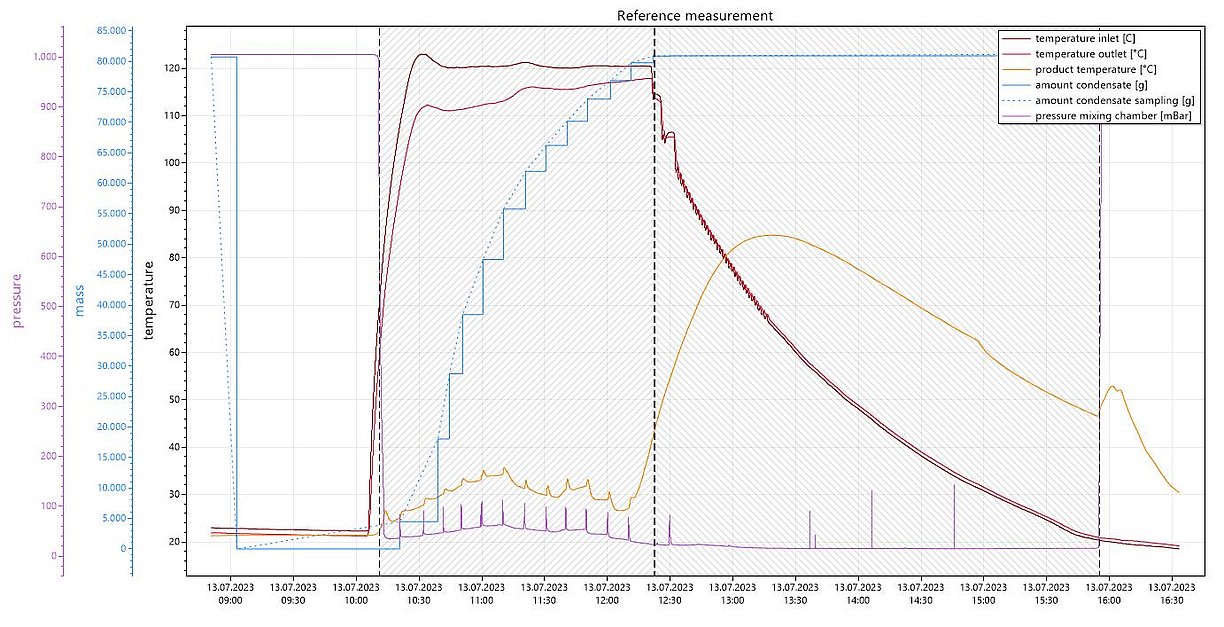

How can the process of vacuum mixed drying be illustrated?

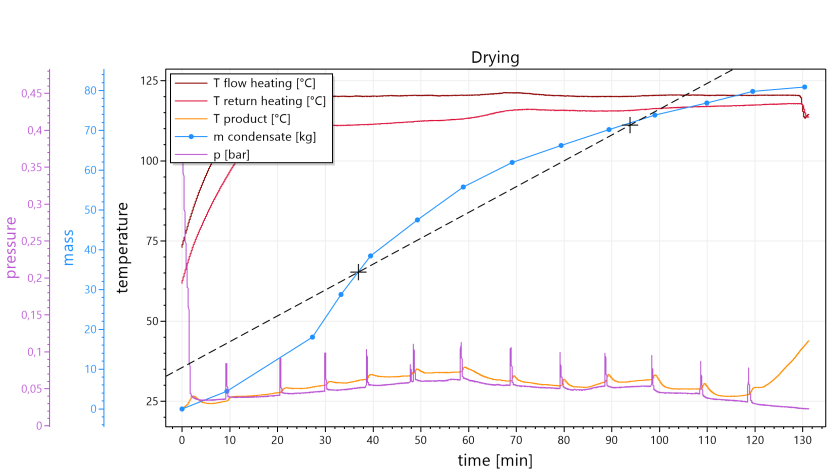

The drying process of a test run can be represented as a diagram as shown here. The time is plotted on the abscissa. Various physical quantities are plotted on the ordinate axis:

- the system pressure in the process chamber,

- the mass of the evaporated liquid,

- the temperature of the mass to be dried and

- the temperatures of the heat transfer medium in the flow and return.

The vacuum mixed dryer is usually filled with the maximum batch volume before the drying process begins. As a rule, the volume of the mixture decreases as drying progresses.

In rare cases, the filling volume remains constant, although the mix becomes drier and lighter. In very rare exceptional cases, there may even be an increase in volume during drying. This increase in volume must be taken into account, as the mixers/dryers must not be overfilled.

How does the heat transfer surface change as the filling level decreases?

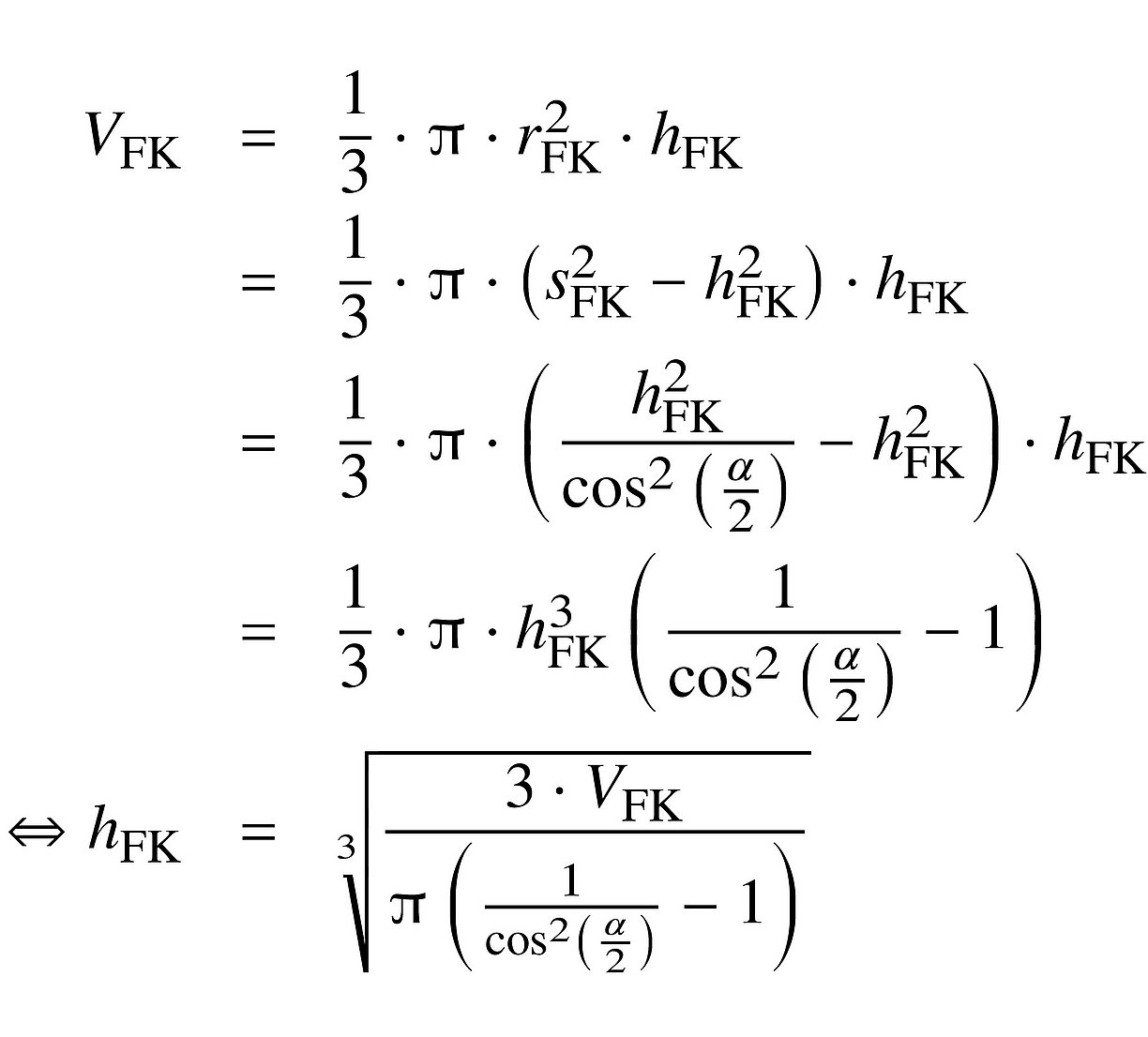

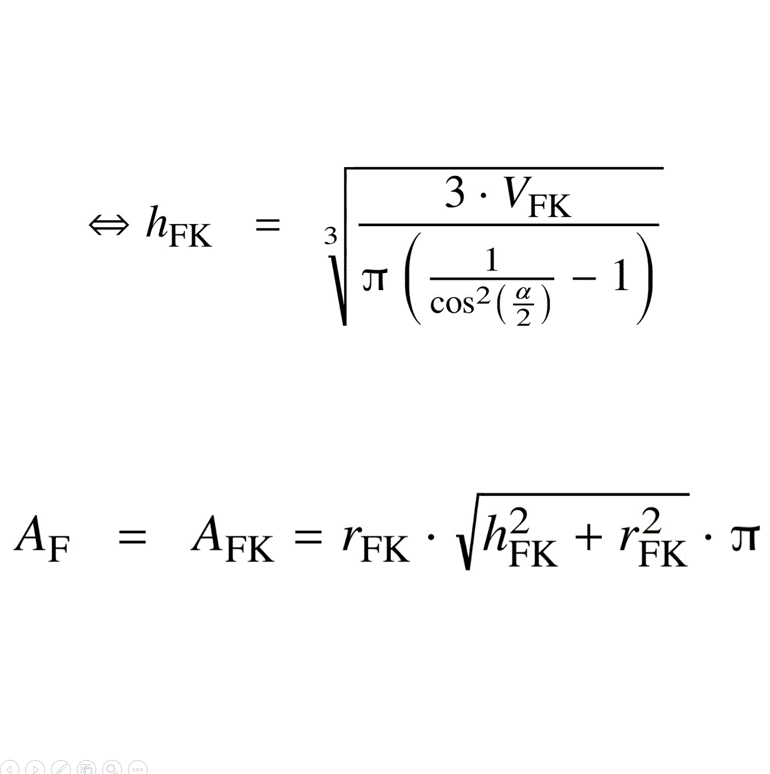

The heat transfer surface of the vacuum dryer changes with the fill level. In this case, the mixing chamber consists of a cone with a cylinder attached to it. In the following derivation, the heat transfer area is calculated for the case where the filling volume is smaller than the conical part of the mixing dryer. First, the filling height hFK in the cone is calculated:

The heat-transferring area in the cone AF is only the area that is in contact with the mixture.

If the filling level in the mixing dryer changes during the drying process, the contact area of the temperature-controlled mixing tool also changes. This situation cannot be described as a closed function. amixon® measures the heat exchange area of the mixing tool in the CAD system for different filling levels. The data is recorded in tabular form and interpolated.

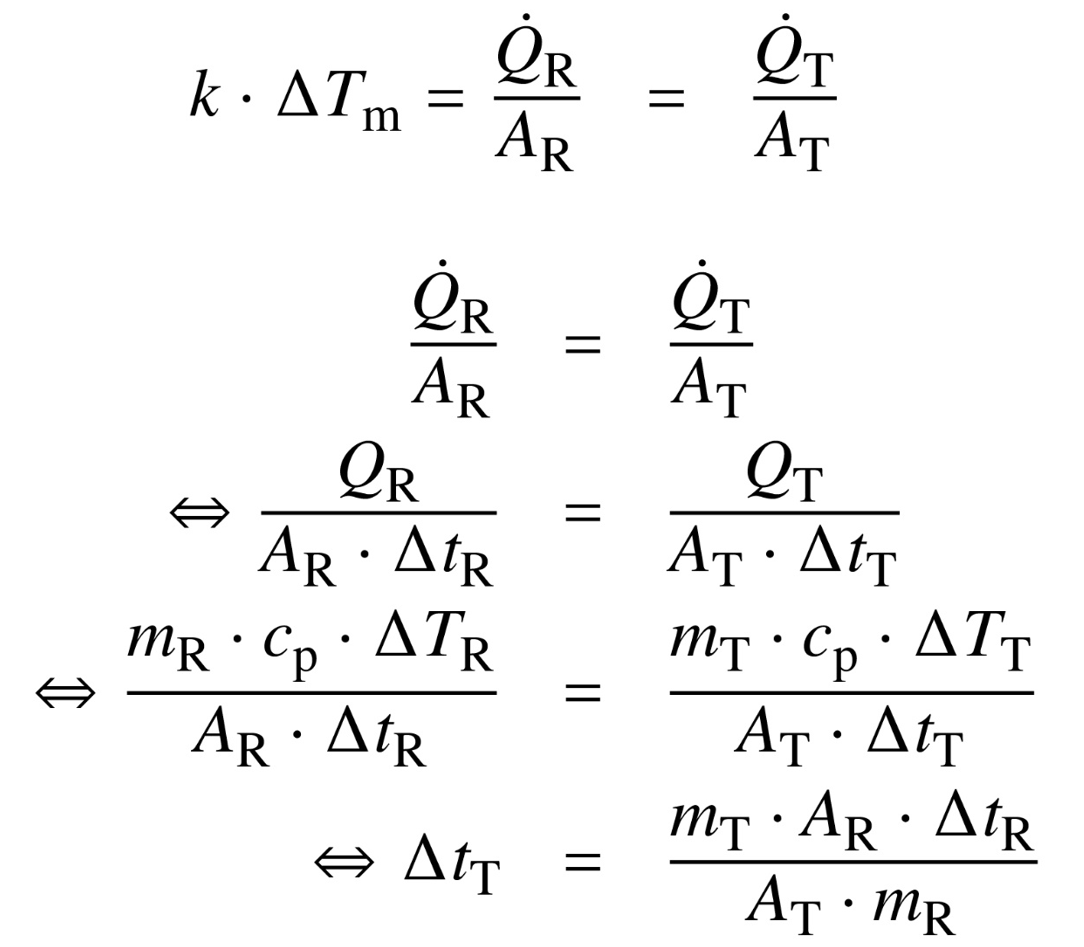

How high is the heat requirement if the vacuum mixed dryer is significantly larger than the test system?

Two indices are introduced below: “R” (reference) for the pilot plant and “T” (target) for the large-scale plant. The drying time is the time from the start of evaporation to the end of evaporation. The following idealized conditions are assumed:

- The process conditions in the test device are identical to the process conditions in the large-scale device.

- Evaporation takes place at a constant temperature.

- Evaporation takes place at a constant system pressure.

- The heat transfer coefficient is the same in both devices.

- The average temperature difference between the heating medium and the mixture is the same.

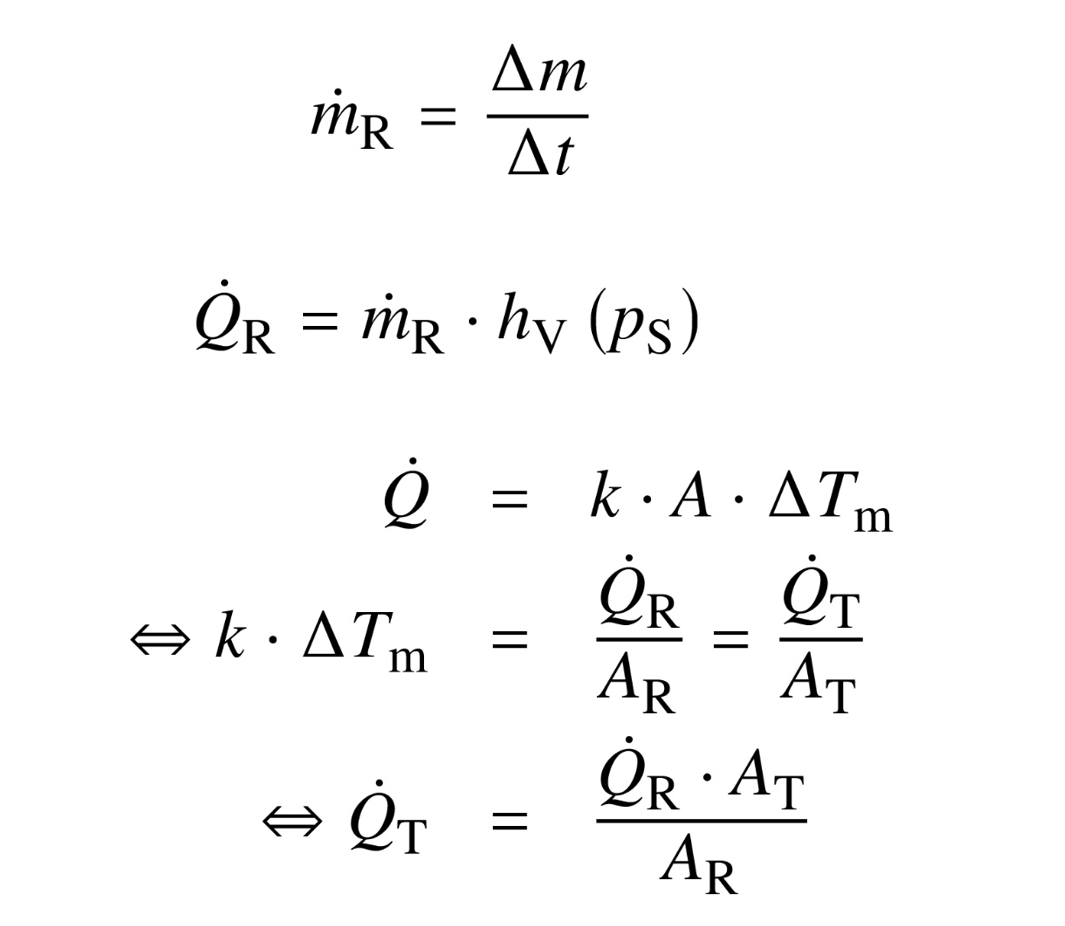

The heat flow “QR ” of the test facility can be determined from the evaporation enthalpy “hv ” at saturation pressure “ps ”. This allows the heat flow through the heated contact surface “AT ” of the large-scale dryer to be calculated as follows.

How long does the drying process take in the large-scale plant?

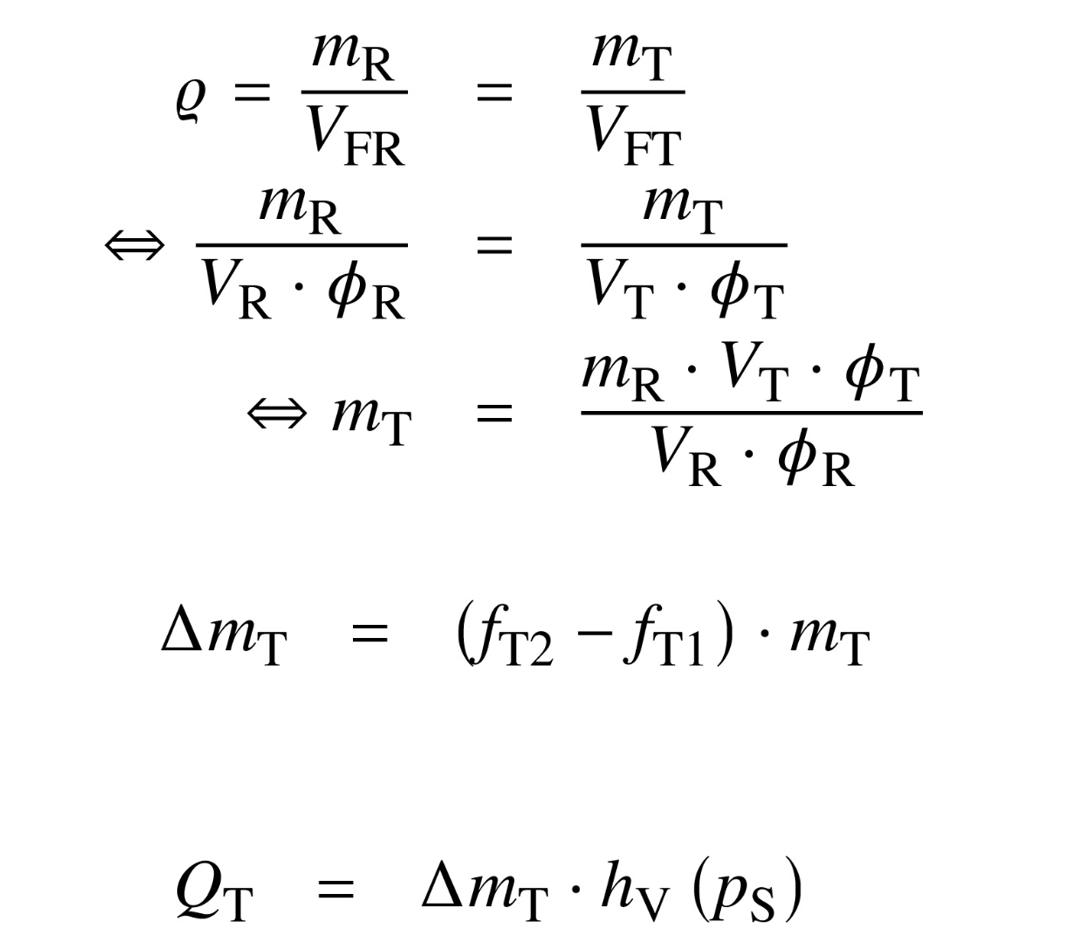

Assuming that the density ‘ρ’ of the moist product is the same in the reference plant and in the large-scale plant, the mass of the product in the large-scale plant can be calculated if the filling degree ‘Φ’ is known.

The mass ‘mT’ to be evaporated in the large-scale plant is given by the moisture contents ‘fT1’ at the end and ‘fT2’ at the beginning of drying.

The drying time in the large-scale plant is then

How large should the heating system for the large dryer be?

The following diagram shows the individual consumption points. Each consumer must be supplied with sufficient projected heat energy. The design factor ‘S’ is used to calculate the heat flow in the heating system. This is based on the heat flow ‘Qvap’ required for evaporation.

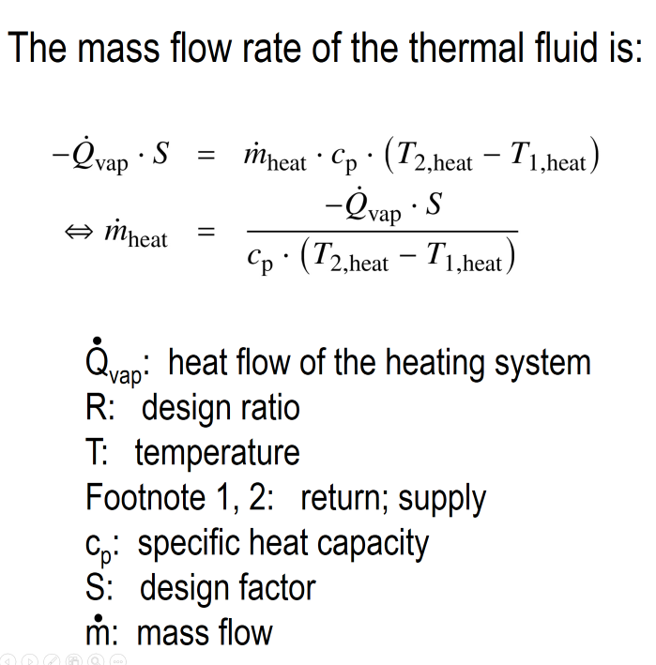

The mass flow of the heat transfer medium ‘Qvap’ is calculated from the specific heat capacity ‘cp’, the inlet temperature of the heat transfer medium ‘T1,heat’ and the outlet temperature of the heat transfer medium ‘T2,heat’. The thermofluid must be distributed in such a way that all consumers are adequately supplied. This means that all areas of the process chamber must be heated evenly. Condensation must be avoided. The moist material must be heated to the extent that steam energy is dissipated. The mixed material temperature corresponds to the evaporation temperature of the adjacent vacuum.

How large should the vapor filter for the large dryer be?

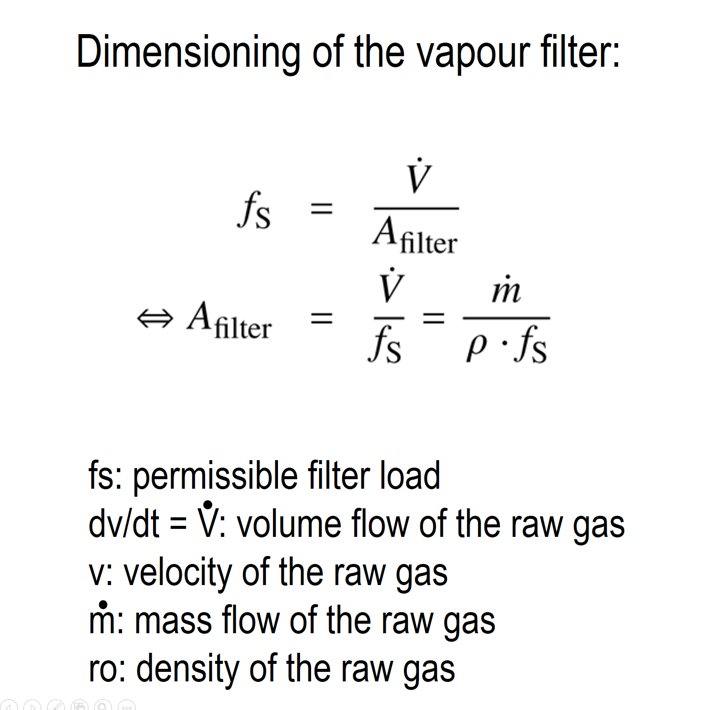

Estimation of the required filter area based on the permissible filter load “fs”

Using the volume flow “dV/dt,” the mass flow “dm/dt,” and the density “ρ” of the vapor.

The velocity of the dust-laden raw gas “v” is

The filter area load “fs” is defined in the unit [m³/h/m²].

How large should the condenser for the large dryer be?

How large must the condenser for the large dryer be dimensioned?

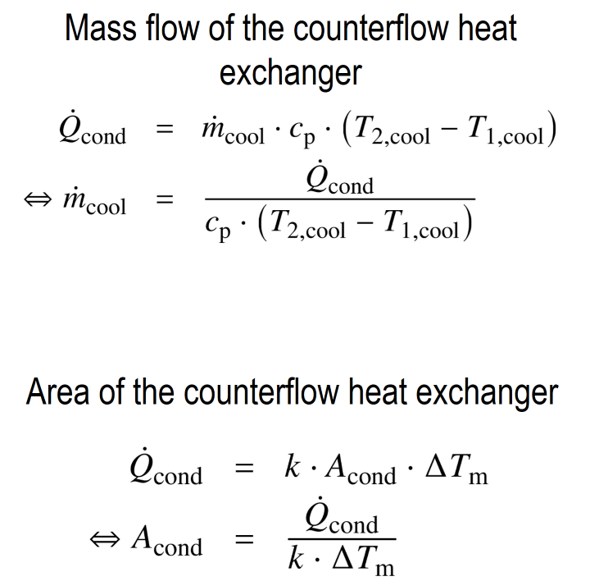

The evaporated vapour is cleaned in the vapour filter and liquefied in the condenser. The heat flow ‘Q̇cond’ must be dissipated. The cooled condensation surface ‘Acond’ serves this purpose.

Taking into account the heat transfer coefficient and the average temperature difference, the mass flow of the cooling medium ‘ṁcool’ is calculated:

When determining the ‘K’ value, the design of the condenser and the expected fouling factor must be taken into account.

A straight line idealises the mass flow of the condensate.

What is the intention when the measured condensate mass flow is averaged by a straight line? This rough approximation allows a comparison with a continuously operated parallel flow heat exchanger. The effects of changing process parameters can be calculated with a very good approximation..

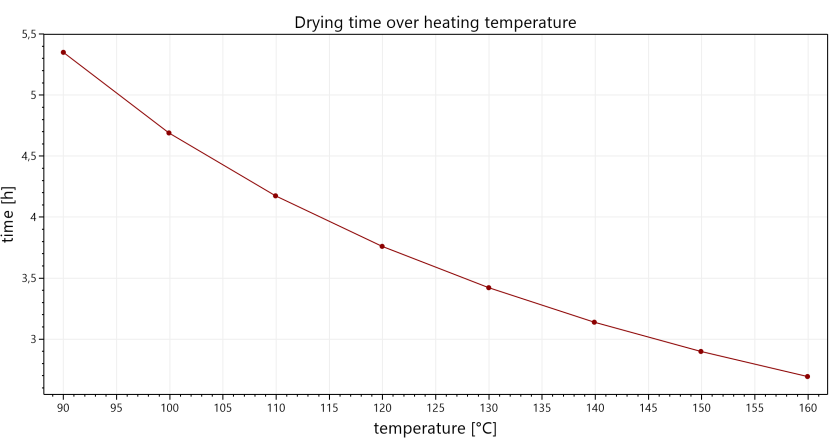

How long does the drying process take in the large-scale system if the temperature of the thermal fluid is changed?

The planned large-scale drying plant can be operated with a warmer or colder heat transfer medium. This changes the drying time. These considerations are made in analogy to the operation of a ‘parallel flow heat exchanger’. The value for ‘T2,heat’ can only be iterated numerically. This allows an interesting curve to be approximated. It enables the drying times to be estimated at different temperatures of the heat transfer medium.

Why does it take longer to cool down dry powder than to heat up wet powder?

When estimating the cooling time “Δ tT,” it is assumed that the same conditions prevail in the pilot plant and in the large-scale dryer. This applies to both the heat transfer coefficient and the average temperature difference between the heat transfer medium and the product temperature. The product in the large-scale plant should be cooled to the same final temperature as was tested in the pilot plant.

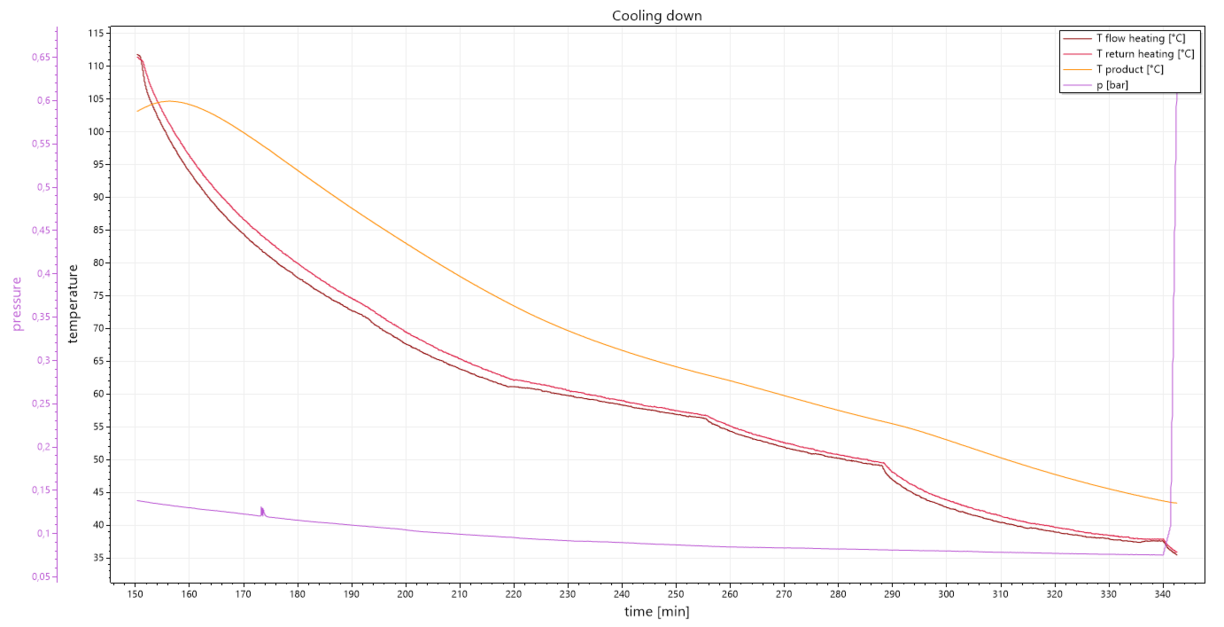

What is striking about the mix cooling in this diagram?

A typical cooling curve is shown below. The cooling of dry powder takes longer than the heating of wet powder. There are two explanations for this:

- A liquid conducts heat much better than most solids.

- The liquid film surrounding a moist particle can wet the heat transfer surface. This promotes heat transfer. In contrast, a dry particle only touches the tempered surface at a few points.

In this case, the dryer was heated with a very high temperature difference. The thermal oil was initially approx. 120°C hot. In this case, the entire thermal oil storage tank must first be cooled in the system flow. This results in the cooling of the drying powder with a pronounced hysteresis.

If water were used as the heat transfer medium, the cooling process would be accelerated.

© Copyright by amixon GmbH