Weighing cells or load cells measure the weight of the mixing goods and the mixer

Wherever bulk solids are manufactured or processed, we want to know their weight. This is the only way to reliably control the quality of intermediate and end products.

A powder mixer is used to refine materials and usually plays a significant role in the value-added chain. But it is only one link in the process chain. The more information is known in connection with dosing, mixing, discharging and the degree of emptying, the better the interaction of the entire plant can be optimized.

Simple load cells can reliably weigh large masses. This also applies when the masses are blended in the mixer. Weighing data is provided in analog or digital form. However, within a plant system, more is needed. The measurement data must be interpreted in process automation. amixon® discusses just one detail in this context that is frequently questioned by customers.

How accurate is mixer weighing?

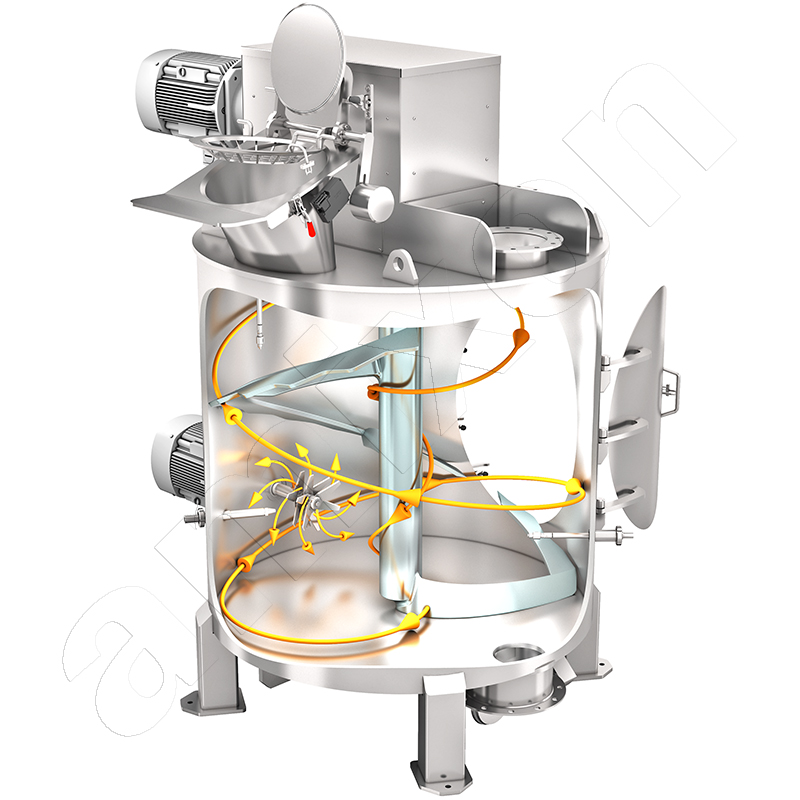

Question: How accurately can the contents of a 5m³ mixer be weighed when the mixer is placed on load cells as shown here?

Answer from amixon®:

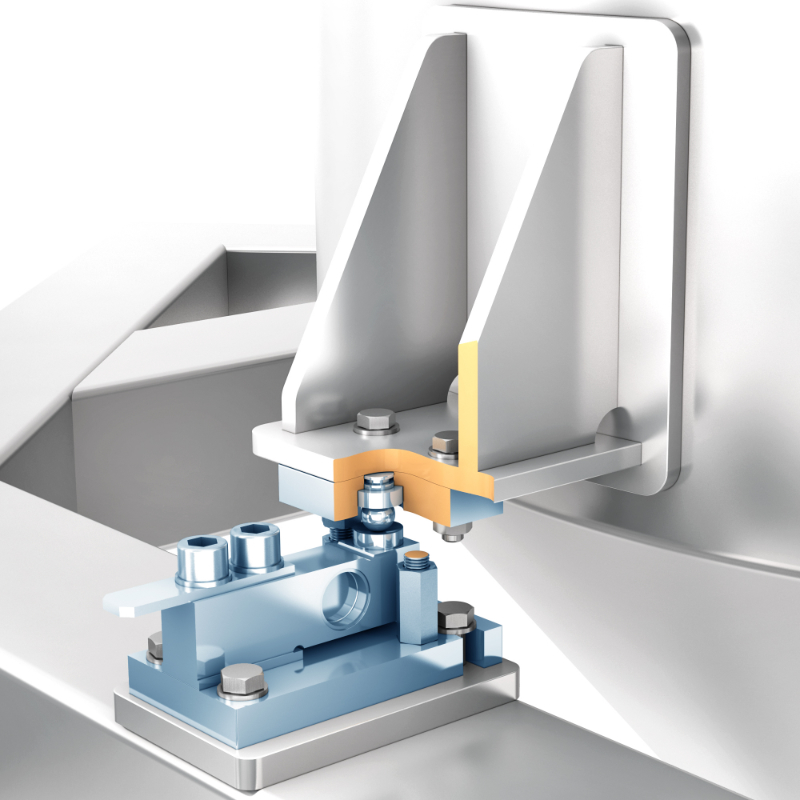

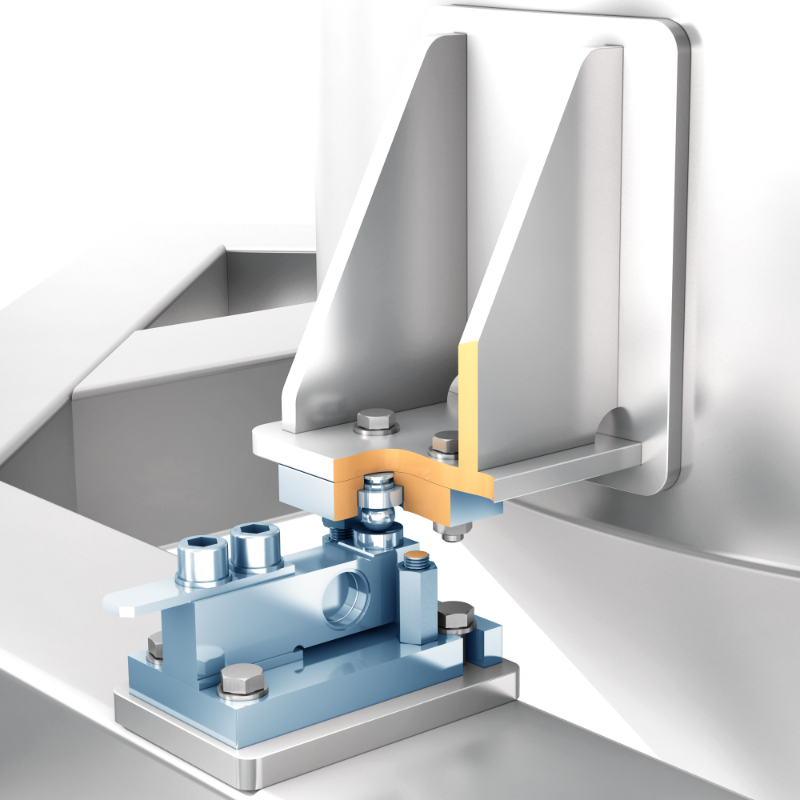

The amixon® mixer shown on the right rests on four load cells. The component shown in blue in the picture above shows the mounting plate and the bending beam of such a load cell. Strain gauges are attached in its round recess (hidden from view). Depending on the load, the beam deforms elastically. If the strain gauges stretch, the electrical resistance increases; if they compress, the electrical resistance decreases.

Digital load cells already have integrated evaluation electronics that measure the current flow and output it as a digital signal. The load is applied via a ball. This ensures that only vertical loads are measured.

Example of weighing accuracy in practice:

1 kg mass generates a vertical force of 9.80665 N at rest.

- The empty weight (tare or net weight) of this amixon® mixer is approx. 48 kN.

- The type designation is VM 5000. The mixer is designed for a maximum batch size of 5 m³.

- This mixer is designed so that it can also mix heavy goods such as salt. The maximum bulk density is approx. 1.2 kg/dm³.

- When filled to the maximum (5 m³), the weight of the mixture is 58.84 kN.

- Together with the weight of the mixer, this results in a total load of 106.84 kN.

- In this case, the mixer stands on 4 digital load cells. The calculated weighing accuracy is 5 N. This corresponds to a powder mass of approx. 510 g. Thus, 0.85 % based on the maximum batch mass of 6 t.

The display shows a relatively accurate value when the mixing tool is stationary. With the help of electronic damping, a relatively accurate value can also be displayed when the mixing tool is rotating.

Before the mixer weighing can be put into operation, the parameters for the scales and the display electronics must be set. To do this, the mixer must be filled symmetrically with a precisely defined quantity. In the case of a calibratable scale, the mixing chamber must be filled with calibrated weights. The electronic signal generated in this way is used to tare the scale.

Container docking station under the discharge fitting of the mixer

Question: If the contents of a mixer are to be filled into several big bags or bulk containers (IBC), it is important that the containers are filled with a defined quantity. Overfilling must be avoided, as must underfilling. Can a mixer scale solve this task?

Answer from amixon®:

In principle, this is also possible if the flow properties of the mix allow it and the mixer's discharge valve is suitable for it. This can be determined in a test at amixon. Depending on the desired dosing accuracy, the filling process is faster or slower.

If you would like to learn more about the topic ‘Container filling or Big-Bag filling directly from the mixer’, please also read our article about our new development. DosiFlap® is a space-saving new development from amixon®. It is also recommended wherever the aspects of ‘ergonomic cleaning’ and ‘sanitary design’ are important.

Note on load cell protection

If welding is carried out during installation, the load cells must be replaced by load-bearing placeholders (dummies). The load cells must be galvanically isolated from the welding currents. Welding currents can destroy load cells.

Your most difficult mixtures should be used for carrying out mixing and discharge tests with DosiFlap®. We offer you ideal test conditions in the amixon® technical centre.

© Copyright by amixon GmbH