Cosmetic powders ideally mixed in the amixon® mixer

High expectations are placed on powdery cosmetic products such as eye shadow, powder or rouge: they should spread well on the skin, last a long time, not crumble or dust. In addition, they are to be treated particularly hygienically like highly pure pharmaceuticals.

Eye shadow, make-up powder and rouge, lipstick and nail varnish are used in tiny amounts per application. Nevertheless, they are a market worth billions. Only high-quality ingredients are used. People who wear make-up appear more radiant because pigments absorb or reflect light, depending on their properties. The effect is enhanced when contouring is combined with techniques such as blush, bronzing and highlighting.

The list of ingredients in a modern rouge is long:

The cosmetics industry has a wide range of raw materials at its disposal:

- Talc: binds sweat and makes shiny areas matt

- Kaolin (white clay): ensures a fine, matt texture and good oil absorption.

- Mica: gives products a shimmering or silky effect.

- Zinc oxide: has a mattifying and antibacterial effect and protects against UV rays.

- Titanium dioxide: serves as a white pigment and UV filter.

- Silica: ensures a silky skin feel and good oil absorption.

- Bentonite: clay that binds moisture and oils.

- Starch (e.g. from corn, rice or potatoes): used as a natural filler or binder, often in combination with talc.

- Methylcellulose powder: improves the feel and texture, often used as a filler.

- Iron oxides: for natural colour shades (brown, red, yellow tones).

- Ultramarine: for intense blue tones.

- Chrome Oxide Green: for green shades, often used in concealing products to neutralise redness.

- Carmine Red: natural red dye, often used in decorative cosmetics.

- Mica and effect pigments attract attention

Due to their fineness, colour and effect pigments tend to agglomerate during mixing. If they are not distributed well enough in the powder matrix, they can leave streaks of colour when applied to the skin. The challenge in mixing is to completely disagglomerate the components. On the other hand, the interference pigments must be preserved. They are used to create holographic effects in nail varnish, eye shadow, highlighters, lipstick and body glitter. The powder mixing process must therefore be carried out with adapted shear energy.

Small quantities of liquid binders are added to the powders. This makes the powders pressable and extrudable. Coupling agents ensure lasting adhesion to the skin until the make-up is removed.

Ultra-fine distribution of the liquid binding agents

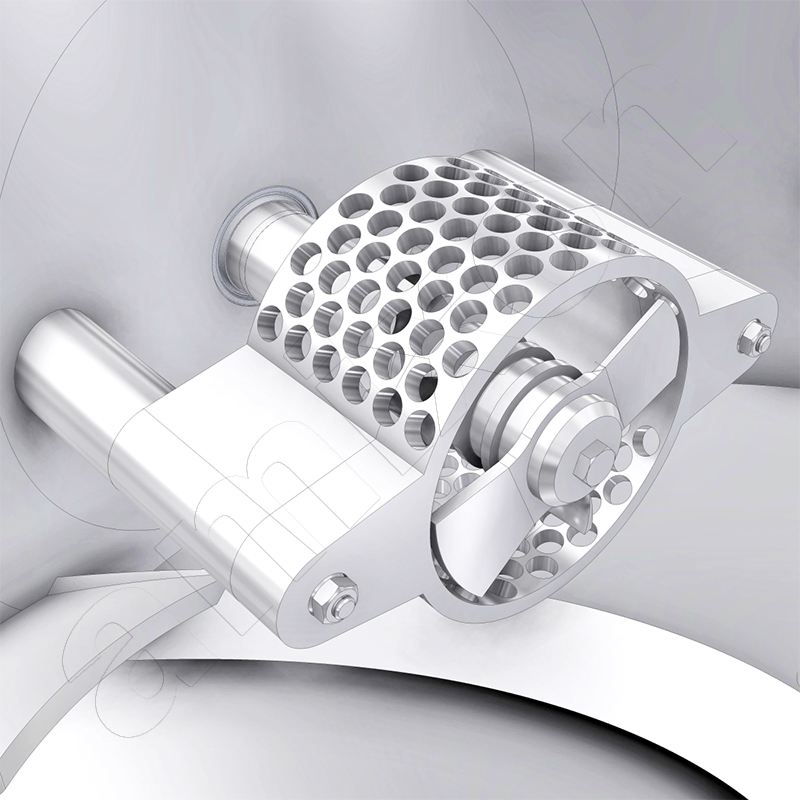

The cutting rotors also support the next step in the manufacture of cosmetics: the ultra-fine distribution of the liquid binding agents. The use of cutting rotors enables the particularly effective homogenisation of liquid additions. Highly viscous liquid additions can be distributed into the powder. They are injected underneath the filling level directly into the area of action of the cutting rotor using a feeding lance. The distribution of the fluid thus takes place directly through vortex, friction and centrifugal effects with increased energy input. The lance can optionally be equipped with a nozzle and can be tempered if desired.

Following a short post-mixing time, the manufacturing process in the mixer is complete. The complete discharge of the mixing chamber takes place without de-mixing - in practice, discharging rates of up to 99.98% or more have been achieved under ideal conditions. Finally, automatic wet cleaning can be carried out using the patented WaterDragon® system.

Learn more:

Ingredient Transparency and the Clean New Face of the Beauty Industry

Mix a wide variety of powders ideally and precisely - with minimal agitation.

Components such as talcum powder, colour and effect pigments and mica particles as well as binding agents are mixed at a low rotational frequency regardless of differing particle sizes, bulk densities and flow properties. The rotating screw conveyor picks up the mixed materials at the periphery of the mixing chamber and conveys them upwards. Once at the top, the goods flow downwards in the centre of the vessel. After 40 to 160 mixer revolutions, technically ideal mixing qualities are achieved that can no longer be improved in practice.

These amixon® mixers are available for your mixing tasks. Put us to the test. We guarantee ideal mixing qualities with gentle processing.

Cosmetic products

The focus is on crushing, mixing and agglomerating. Some products are launched in liquid form. The powders are then ‘high-shear’ suspended:

- Face cosmetics: mineral-based foundations, setting powders, bronzers

- Decorative cosmetics: highlighters, compact powders (e.g. as agglomerated powders or pressed into tablets), rouge powders

- Nourishing cosmetics: mask powders (based on clay or activated carbon), peeling powders, enzyme peelings

- Body cosmetics: body powders (talc), glitter powders for the body

- Hair care products: dry shampoo, hair thickening powder

- Hair dyes of plant origin: henna powder, indigo powder, amla or cassia powder

- Hair dyes that oxidise: lightening powder (e.g. bleaching powder), dye powder that is mixed with water or a developer.

- Herbal hair dyes

- Pigment-based products: pure colour pigments for DIY cosmetics, micaceous pigments (e.g. for shimmer or shine effects)

- Speciality products: sun protection powders, nail art powders (e.g. acrylic or dip powders for artificial fingernails)

© Copyright by amixon GmbH