Product life cycle for our machines

Even at the end of their useful life, machines can make a valuable contribution to the circular economy: the amixon® end-of-life concept shows different ways of conserving resources and avoiding waste.

amixon® wants to enable its customers to operate climate-neutral, circular production facilities. For this reason, the concept of circular economy is taken into account throughout the entire portfolio as part of sustainable product design. At the end of their service life, the resources and materials used should be optimally recovered and reprocessed.

20 to 30 productive years? Not uncommon for amixon® machines. Because with the right maintenance and targeted retrofitting, the efficiency and reliability of the systems can be maintained over a long period of time. This is precisely the aim of amixon® Excellent Services: to extend the service life of a vertical mixer or reactor to a maximum with services tailored to your needs.

Sustainably continuing a long machine life

Even if it happens later rather than sooner with an amixon® machine: At some point, it will eventually be taken out of production. What happens then?

For customers who want to dispose of their equipment themselves:

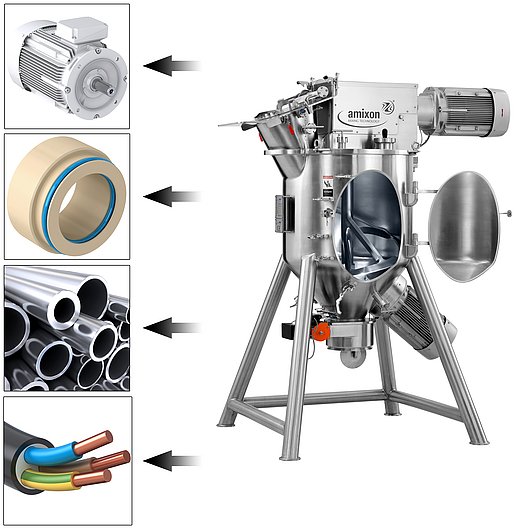

The core objectives of progressive waste management are to protect the environment, to pollute as little as possible and at the same time to achieve optimum recycling from the waste. To achieve the best possible waste recycling, sort the mixer into the following components and material types:

Mixer components / drive technology: electric motors, gearboxes, etc.

Polymers (plastics): Seals, radial shaft seals, door stoppers, hoses, etc.

Metals: stainless steel, mild steel, etc.

Electrical components: All electrical and electronic equipment designed and manufactured to operate on AC voltage or batteries, as well as their components, accessories and cables

Hazardous waste: Gear oil, hydraulic oil, etc.

Drop-off at the recycling or waste collection center