Precision mixers for Instant Food

The principle has always been that food should not only taste good, but should also be conveniently available. Today, instant foods are offered as hot or cold meals. Instant food is of higher quality the more nutritious it is and the more natural it tastes. Preparation must be simple, ideally with a " success guarantee." In addition, the longer an instant food can be stored without loss of quality, the more interesting it is - ideally regardless of ambient temperatures in winter and summer and in a wide variety of climates. Instant food is a long-term food! The crucial point is the long-term stability / minimum shelf life of the instant food.

You may also be interested in the article on instant seafood.

Benefits for private consumers

In nearly every household today there are packet soups, powdered sauces, sauce dressings, salad dressings, cold sweet soup and pudding powders, baking mixtures, potato flakes for purees, instant noodles or rice. They have a long shelf life, can be stored in a space-saving manner without cooling, are very tasty and quick to prepare.

The life plans of many people in today’s urban, advanced civilizations differ significantly from those of our forefathers. Life in families with lots of children required fixed meal times back then. Food preparation was in the light of shortages, it was laborious, strenuous and often varied little. It was influenced by what was regionally and seasonally available. With the start of the first industrial revolution about 150 years ago, a new age of nutrition began, characterized by the division of labor and globalization. More and more people became disengaged from farming and agriculture to work in factories. Newly emerging food factories specialized in the processing of all possible kinds of food crops. Learn more about the history of instant meals here.

It is interesting that we are seeing a countermovement in some areas today. Some start-ups are substituting highly processed foods with largely natural ones. They are creating instant food at a technologically high level by applying long-forgotten home recipes used by their ancestors. The number of single households, particularly in cities, is rising and indeed across all age ranges. Quickly and easily preparing a small hot meal, at no matter what time, whether at home, at the office or on the go, with friends or alone is perceived as normal. This convenience is immediately derived from the benefits of instant foods. The general rule is that, when the water activity of a dry ready meal is less than 4 %, this ensures sufficient microbiological stability. The instant food, allowing for clean production and adequate packaging, remains naturally durable for a long time even without cooling; free of toxic molds such as mycotoxins and aflatoxins. Liquefied, highly concentrated foods can only exhibit similarly good storage stability with difficulty.

Instant food is also a convenient product. Every ingredient is already contained in the sachet in the right quantity. This also ensures that there are no leftovers. When it comes to preparing it, no cooking skills are required. Because instant foods offer a “success guarantee”. All that is needed is to add the right amount of liquid and to keep to the timings in order to produce a tasty meal. The portioning of water and powder is done highly accurately and hygienically in vending machines. These mostly provide vending machine soups with a wide variety of flavors.

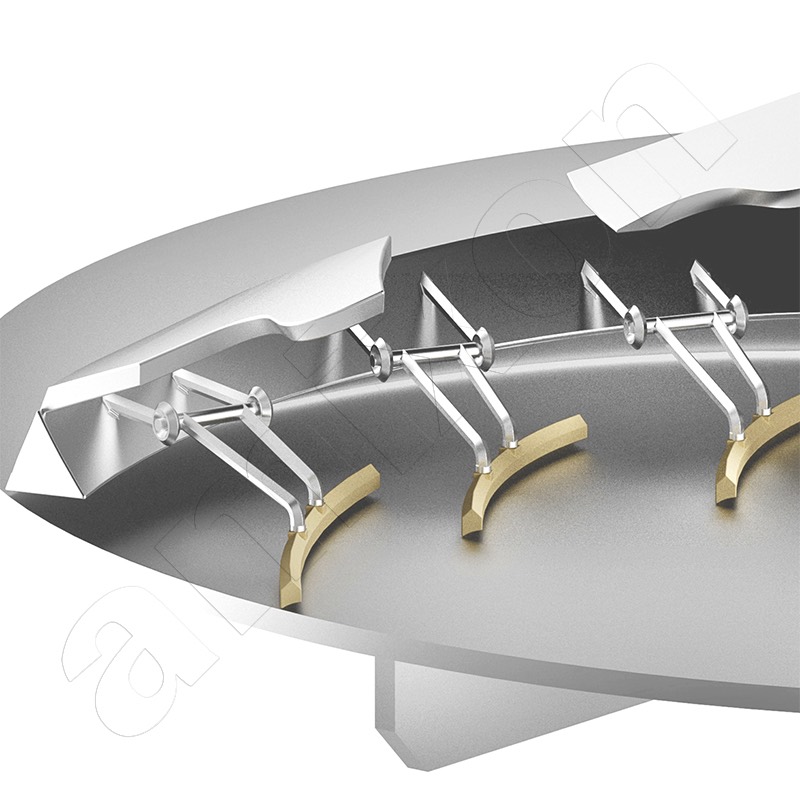

Liquid additives can be distributed micro-fine into the powder. On the left you can see the intensive preparation: the liquid is injected into the turbulence area of the agitator. On the right you can see the gentle liquid material mixing: the liquid is sprayed microfine and the powders are fluidized in the mouth area of the nozzle.

This requires effective preservation methods.

Dry food mixtures can have outstanding instant properties and they can taste extraordinarily good. With regard to long life, particularly high importance is attached to the dry mixing process. It must be gentle to the ingredients and take place preferably without any oxygen, and, if possible, it should happen immediately before the filling and sealing process.

If you take into account that the taste of non-perishable foods changes, then you can cure meat and fish in salt or smoke it, ferment white cabbage to make sauerkraut, preserve fruit in alcohol or wine vinegar, or cook fruit preparations to make jam and marmalade. Chemical preservatives such as sorbic acid, sodium sorbate, potassium sorbate, calcium sorbate, benzoic acid, sodium benzoate, potassium benzoate and calcium benzoate have little influence on the taste but require declaration. Their effect is specific in different ways. Some preservatives kill fungal spores, others deactivate microbes or enzymes. Their use requires a particularly homogeneous, even distribution. For nutritional physiology reasons, their use should be kept to a minimum. Some instant food manufacturers advertise the use of conservation agents that are identical to nature. amixon® mixers can distribute and mix very small quantities of conservation agents (powder or liquid) microfine in large batches.

Physical preservation methods first and foremost extend to the removal or deactivation of the water.

Vacuum freeze drying is the highest quality form of preservation here in terms of retaining taste and structure - but unfortunately also the most expensive. Unlike simple hot-air drying (dried fruit), where the capillaries of the fruit shrink and stick together, with vacuum freeze drying, the taste, color and also form of the fruit are preserved, even after subsequent soaking. Freeze drying can also be excellently used for meat preparations. After adding hot water, the spicy flavors from the Maillard reactions soon come back.

The most cost-effective way of removing water takes place in the drum contact dryer (potato flakes, starch, cereals, cheeses...). But the more elaborate spray drying method is also widespread (baby food, dietary foods, plant extracts). Both drying methods require that the food is liquefied beforehand into a pumpable or even sprayable consistency. Spray-dried foods are usually easy to agglomerate and then have outstanding instant properties. The particles produced are easily wettable with water, dispersible or soluble. For types of food that come in pieces, such as fruit, fish and meat, hot steam sterilization at 180°C in an autoclave at a pressure of at least 12 bar is suitable. The deactivation of enzymes and microorganism caused by this leaves the water in the food. This applies equally to the traditional method of bottling for food in jars, which has been practiced in private households for generations to this day. A defined cooking period displaces the atmospheric oxygen and deactivates microorganisms. The vacuum in the top space of the container shows whether the goods have remained intact. To prevent glass breakage of UV light, the industry likes to use cost-effective tin cans, particular for goods from overseas. Vacuum packaging or inert gas packaging also makes dry foods last longer (seeds and nuts). In the absence of atmospheric oxygen, the metabolism of microorganisms is largely blocked. Deep freezing at temperatures below minus 18°C is widespread, which also does little harm to taste and flavor. Here too, all the water remains in the food. Color, shape and texture are better preserved the faster freezing takes place.

Particularly tasty meal combinations are possible when the side dishes, vegetables and the meat are partly cooked separately and shock frozen and sealed in trays after being prepared. This method of preserving is comparatively expensive, however, and probably less sustainable with a view to environmental protection. The deep-freeze chain through to being consumed must not be interrupted.

amixon® mixers work extremely gently and require a minimally short mixing time. This applies to goods at room temperature or to deep-frozen goods in cold stores. (Pizza toppings, vegetable mixes, bacterial cultures, cheese graters, ham strips, paprika strips, cereals, biscuits, chocolate flakes, ice cream).

Another physical preservation method should be mentioned at this point for the sake of completeness, namely exposing the food to ionizing radiation. In Germany, unlike abroad, this irradiation process is not so popular and only allowed for dried, aromatic herbs and spices and must be marked. According to the World Health Organisation (WHO) as well as the EFSA, the irradiation of food with gamma, UV and X-rays for the purpose of sterilization is harmless to health.

In addition to other options for disinfection and sterilization, steam sterilization can also be performed in the mixer.

The amixon® mixer-reactor can be temperature controlled and is pressure and vacuum tight. Spices, vegetables, fruits are placed in the heated mixer-reactor. Sterile steam is introduced, increasing the system pressure. Vacuum is then applied to remove the moisture previously introduced. This results in cooling of the mixed goods. This method can also be used, for example, to sterilize culture media for sensitive noble organisms. This method is widely used for professional mushroom cultivation.

The method of mixing influences taste, granulometry, visual appearance and also mouthfeel.

In the amixon® precision mixer, the user can homogenize extremely gently (minimum energy input) or deagglomerate intensively (with high energy input). Often both methods have to take place one after the other. This is also called multistep method. a) Dextrose, maltodextrin, salts, spices, starch, oleoresins, fats, oils, flavors are intensively mixed. Whirlers, choppers, cutting rotors or HighShear blades are also used. After a few minutes, the mixer stops. Sight spices, freeze-dried dill tips, onion rings, pieces of peppers and cauliflower, leafy vegetables, noodles, etc. are added. Now the blender starts again but only for 30 seconds. (avoidance of shear crystallization). With a slow rotation frequency, a gentle "under-lifting" takes place. Then an ideal mixing quality is achieved. All coarse constituents are retained. The mix is not warmer than before. The mix is discharged free of segregation. Filling takes place in bags, pouches, cans, jars.

State-of-the-art food factories are highly automated, so that almost all process steps are carried out by machine: raw material reception (dry materials as well as liquids), sampling and quality determination, conveying and storage, metered discharge, charging above the mixer, blending and filling. As with the mixer, the structure of the powders must be preserved in all other process steps. Any energy input must be reduced to the minimum necessary. Compaction and shear stress must be avoided.

Processing of instant food from raw material to finished product - Image source: AZO GmbH, Osterburken. Standardized interfaces (screwed sanitary flanges or via TriClamp) guarantee pipe connections free of dead space for the raw material feed, the ventilation and for the discharge of the finished mixes. The same applies to the electrotechnical and sensory integration.

Instant hot meals offered today meet the highest quality criteria.

Even when the food powder exhibits the mentioned attributes, such as the taste or color, it cannot be definitely called instant food yet. The powder must react as expected when the liquid is added. It must demonstrate a typical instant solubility. The air in the powder must escape from the bulk material to the extent that the powder penetrates and lowers the liquid level. Sinking behavior, solubility and dispersibility must meet the consumer’s expectations. The consumer also expects good storage stability and pourability when they empty the packaging.

All formulation ingredients must be able to be wetted similarly quickly by hot water, sink and disperse or dissolve well. This is difficult in view of the high fat content.

Many components must be prepared accordingly. Porous granules fulfill these arrangements much better than a dust-like particle. Gentle mixing is required. The experience of four decades has shaped the development of amixon® mixers: freeze-dried dill tips, cauliflower, broccoli, onion rings, pasta pieces, fragile vegetables, fruit, agglomerated powders, lecithin powders, fat powders or shortenings are gently homogenized.

ComDisc® tools are manufactured to be wear-resistant. They comply with European and US hygiene requirements. ComDisc® tools can completely empty amixon mixers except for dust deposits. Depending on the size of the drain fitting, complete emptying is faster or slower. Here emptying of a 2 m³ batch from HM 2000.

amixon® mixers can also process "semi-solid" goods. The homogenization of cold, pasty masses is particularly demanding if the mechanical energy input is to be minimal.

Unlike in kneaders, cutters or extruders, the energy input in the amixon® mixer is much lower with the same mixing quality and shorter mixing time. Unlike powders, semi-solid masses are not packaged in bags, sachets or cans, but are formed, rolled or coiled as so-called instant food cubes. Worldwide, many hundreds of amixon® mixers are working in all areas of food production and especially in the production of instant food. Typical batch sizes are 400 liters to 4000 liters.

Tests serve to gain knowledge. Innovative new developments follow from this.

The knowledge described above comes from our experience, which we have gathered over some 40 years. Whether the statements also apply exactly to your products can only be confirmed by mixing tests with original products.

At this point, we would like to repeat the original statement of the technical director Ludger Hilleke: "Although our company only manufactures in Paderborn, Germany, we have test centers and test mixers available for our customers in China, Germany, India, Korea, Thailand and the USA. There we can work out and fulfill the quality criteria with the original products of our customers. We sincerely invite you to arrange trials with us. We guarantee confidentiality. Already in advance we assure you first-class mixing results and a particularly high information gain!

Tests in the technical center are the best prerequisites for your new mixing machine to be designed correctly. This also includes the liquid additives. With a mixer from our production program, your products are then processed quickly, coolly, gently and homogeneously. In addition, it is quick and easy to clean.

© Copyright by amixon GmbH

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/HM_5000_mit_Person_und_Stroemung.jpg)